The constituents of olive bark / by Frederick B. Power and Frank Tutin.

- Power, Frederick B. (Frederick Belding), 1853-1927

- Date:

- [1908?]

Licence: In copyright

Credit: The constituents of olive bark / by Frederick B. Power and Frank Tutin. Source: Wellcome Collection.

4/20 (page 905)

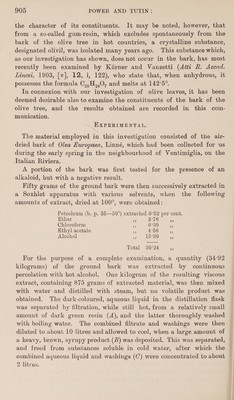

![the character of its constituents. It may be noted, however, that from a so-called gum-resin, which excludes spontaneously from the bark of the olive tree in hot countries, a crystalline substance, designated olivil, was isolated many years ago. This substance which, as our investigation has shown, does not occur in the bark, has most recently been examined by Korner and Vanzetti (Atti R. Acccid. Lincei, 1903, [v], 12, i, 122), who state that, when anhydrous, it possesses the formula C20H24O7 and melts at 142*5°. In connexion with our investigation of olive leaves, it has been deemed desirable also to examine the constituents of the bark of the olive tree, and the results obtained are recorded in this com¬ munication. Experimental. The material employed in this investigation consisted of the air- dried bark of Olea Europaea, Linne, which had been collected for us during the early spring in the neighbourhood of Ventimiglia, on the Italian Riviera. A portion of the bark was first tested for the presence of an alkaloid, but with a negative result. Fifty grams of the ground bark were then successively extracted in a Soxhlet apparatus with various solvents, when the following amounts of extract, dried at 100°, were obtained: Petroleum (b. p. 35—50°) extracted 0'32 per cent. Ether Chloroform Ethyl acetate Alcohol 3 3 3 3 3 3 3 3 376 6-30 4-56 15-30 3 3 3 3 Total 30-24 For the purpose of a complete examination, a quantity (34-92 kilograms) of the ground bark was extracted by continuous percolation with hot alcohol. One kilogram of the resulting viscous extract, containing 875 grams of extracted material, was then mixed with water and distilled with steam, but no volatile product was obtained. The dark-coloured, aqueous liquid in the distillation flask was separated by filtration, while still hot, from a relatively small amount of dark green resin (A), and the latter thoroughly washed with boiling water. The combined filtrate and washings were then diluted to about 10 litres and allowed to cool, when a large amount of a heavy, brown, syrupy product (B) was deposited. This was separated, and freed from substances soluble in cold water, after which the combined aqueous liquid and washings (C) were concentrated to about 2 litres.](https://iiif.wellcomecollection.org/image/b30613176_0004.jp2/full/800%2C/0/default.jpg)