Almost all the tools we use are mass-produced and machine-made, but when you need a clamp that can seal a blood vessel without crushing it, only the hand and eye of a skilled toolmaker will do.

“People think these instruments are popping out of a machine. They’re not. Someone’s stood there for hours making them,” explains Alyson Nisbett, director at surgical instrument makers Platts & Nisbett.

As she shows off the work benches, vices, and files that are the tools of her company’s trade, Alyson reflects on the reaction when medical professionals visit:

“They are like, ‘Wow, okay, I’ll take a bit more care of these instruments now I know what goes into making them!’”

We are standing in a red brick building on a residential street a few miles from the centre of Sheffield. This is Platts & Nisbett’s home. Here, surrounded by largely traditional tools, some of the world’s most skilled metal workers are crafting surgical instruments for use by some of our most skilled surgeons.

At one of the benches, Paul, with a small file in hand, is working on the teeth of a DeBakey clamp. “You’ve got to be very delicate. Not too rough with your hands,” he explains as he gently files away.

“A machine can’t do this. The teeth are too fine. The idea of these teeth is that when the surgeon clamps the vessel, it stops the flow of blood but doesn’t crush the vessel – that’s why the teeth have to be so fine.”

The lower courtyard at Woodfold Works, Sheffield. With a history dating back to the 1880s, it is part of Sheffield’s steel heritage, and represents the continuing tradition of craftsmanship.

Alyson was two years old when Platts & Nisbett was established by her father, in 1977. She joined the business aged 19 and is now the owner and director.

On the left Alyson holds a collection of SPAIRE hip retractors. On the right, James works at machining the forgings.

The raw material for many of the instruments is medical grade stainless steel. The retractor forgings on the right are hand crafted to make West and Weislander self-retaining retractors. These are used to hold soft tissue apart during surgery. The manufacturing process involves 68 steps.

The company, co-founded by Alyson’s father, has been making surgical instruments since 1977. Using hands, hammers and vices to craft bone-cutters, clamps, and retractors with exceptional care and skill.

These skills are in a critical state. Surgical instrument-making is on the Heritage Craft’s red list of endangered skills. The team at Platts & Nisbett is acutely aware that the craft will be lost if knowledge is not passed down. They offer apprenticeships, but they’re expensive for the company.

“Apprentices don’t make us any money for the first few years. They are a cost. And we don’t get funding from the government. You just hope you pick the right people, and they stay.”

When asked what qualities she looks for in new recruits, Alyson is quick to answer: “Perseverance.” “It takes five years to learn. You’re looking at about 10,000 hours of training, so that’s a lot of time.”

It takes that long to learn how to spot the exact shade of orange required when heating up the ends of a clamp before curving them, or to know how to file an instrument without stressing the metal, or to know how to ensure a pair of forceps has the right balance in a surgeon’s hand.

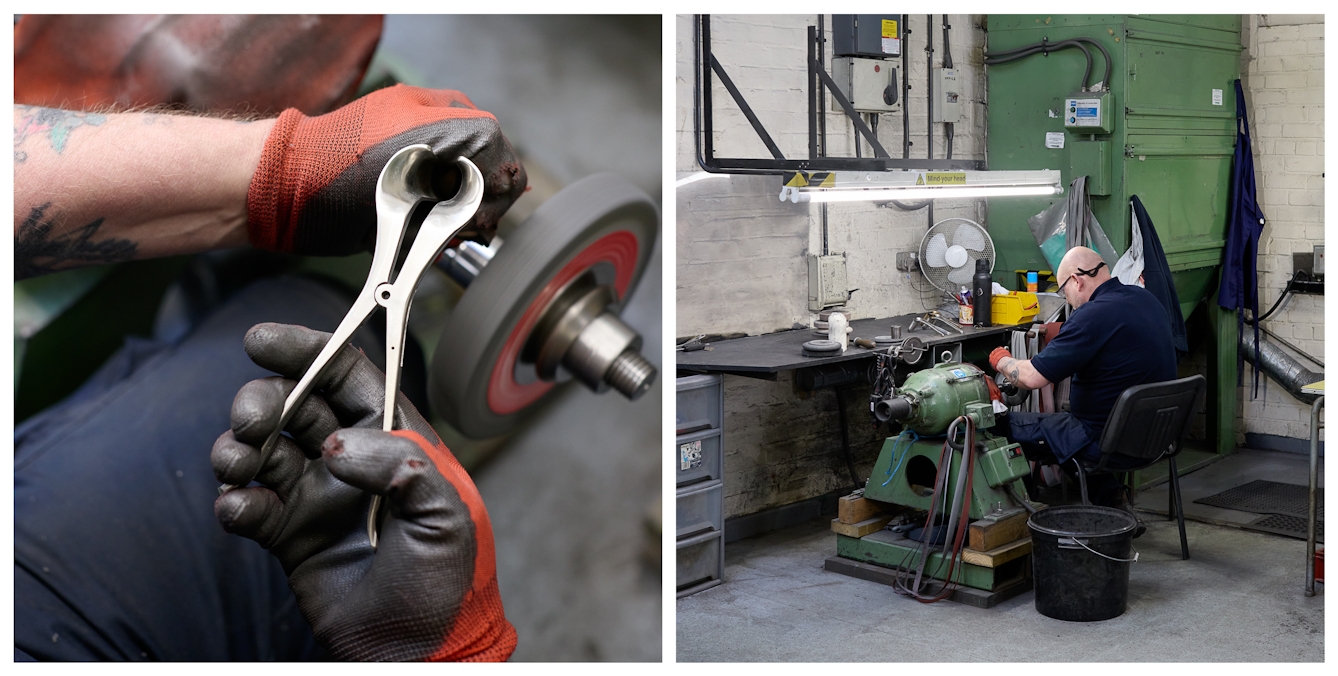

Carl (left photo) and Paul (right photo) have over 48 years combined experience working as surgical instrument makers. They both completed the five year Platts & Nisbett apprenticeship which involves over 10,000 hours of training.

Carl is filing inside the box joint of a Satinsky clamp with a needle file, to ensure there are no burrs and the clamp fits together smoothly. Paul is working with Carl to carefully hand-bend the clamp to the required shape.

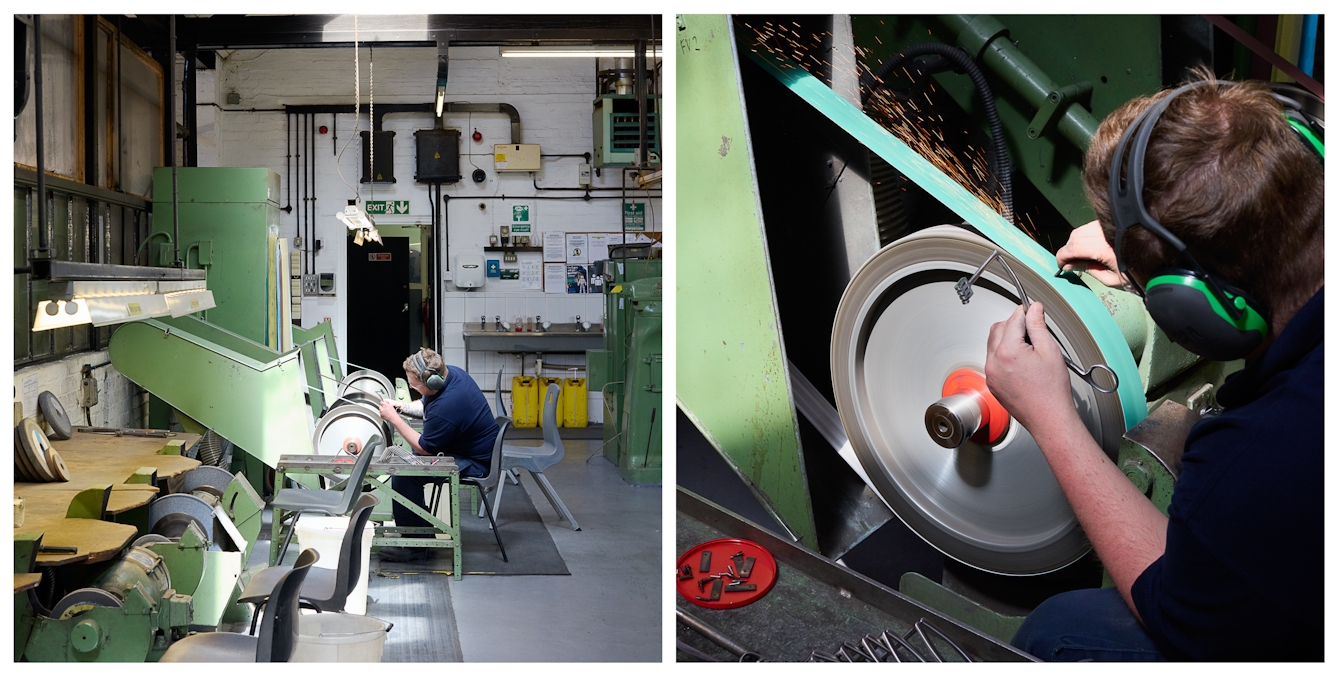

Joe, a surgical instrument maker, is belt-grinding SPAIRE hip retractors, which are exclusively manufactured by Platts & Nisbett. SPAIRE stands for “sparing piriformis and internus, repair externus”. These are used during a muscle-sparing posterior approach in hip replacement surgery, which helps to preserve muscles and soft tissues during surgery. Each retractor is handmade requiring 41 manufacturing steps.

Scott, a linisher/polisher, is working on an Eisenhammer retractor which is used in proctology. Scott came to Platts & Nisbett bringing his transferable skills from the cutlery industry.

Carl has been with the company for 32 years. He’s currently standing by a vice working on a small Castaneda clamp. “You know this instrument is going to be used on children. That’s why you always try your best, it’s got to be the best. You don’t want to think there’s some shoddy instrument being used in a hospital made by you.”

That sense of responsibility is felt by all at the company.

“At the end of everything we do, there’s a patient. And one day that could be you, it could be your son, daughter, someone you care about. You have to know you’re producing the best product you can,” Alyson stresses.

The care and commitment that Platts & Nisbett pours into each piece does not go unrecognised in the surgical rooms. “We get testimonials from surgeons that are happy with their instruments. We recently got a thank-you letter. That’s quite old-fashioned, isn’t it? Usually it’s an email. When we get feedback like that, I do share it with the staff because it’s important for them to know they are making a difference.”

The pattern room at Platts & Nisbett is always an interesting place for visitors, which include surgeons and operating theatre staff. These master patterns are used during manufacture, with each handmade surgical instrument being produced to a tolerance of +/- 0.25mm. The master patterns are gold plated for identification.

On the left, Alyson holds a Norfolk & Norwich retractor. On the right, Julie, the business development manager, holds a purse string forcep. This is used to clamp tissues in colorectal surgery, such as the intestine or major vessels, to facilitate the placement of a purse-string suture.

A selection of atraumatic vascular clamps. The word atraumatic translates to non-traumatic, therefore the quality of the teeth is vital. They must intermesh perfectly so the instrument can clamp the blood vessel and stop the flow, without causing damage. The tension or “set” of the instrument is done by hand, and the instrument must feel smooth and close progressively on each catch.

Making a difference matters to Alyson. At the back of the factory, in the company’s small boardroom, there’s a folder on the table. In it are photos of children who have received corrective surgery thanks to a medical charity which Platts & Nisbett donate instruments to.

“This photo shows a baby’s heart. The size of a strawberry basically. You’re looking at a heart, and our instruments around it,” explains Alyson with pride.

“We are not just here bashing out lumps of metal. Our instruments are either going to be life-changing or life-saving.”

Alyson puts the folder back down as she goes out to discuss a new order with her team. Here, in this Sheffield workshop, they are striving to save the metal-crafting skills relied on by surgeons when they save lives.

About the contributors

Carmel King

Carmel King photographs makers and manufacturers across the UK, documenting British craft and industry. She is particularly interested in capturing regions of the country that are known for specific crafts and long-running family firms, where skills and knowledge are passed down through generations. In October 2022 Merrell published ‘Made in London‘, which Carmel King co-authored with Mark Brearley, which looks behind the scenes of 50 workshops and factories across the capital.

Steve Duke

Host and founder of 'The Factory Next Door' podcast, Steve has been a journalist for more than 20 years. Previously, he was the BBC’s senior economics producer. During his career, Steve has reported from more than 60 countries, winning numerous awards for his focus on the people behind the business and economic headlines.