Health and safety research 1975 : an account of the executive's research testing and laboratory services incorporating the annual report of the Safety in Mines Research Establishment.

- Health and Safety Executive

- Date:

- 1976

Licence: Open Government Licence

Credit: Health and safety research 1975 : an account of the executive's research testing and laboratory services incorporating the annual report of the Safety in Mines Research Establishment. Source: Wellcome Collection.

25/66 (page 15)

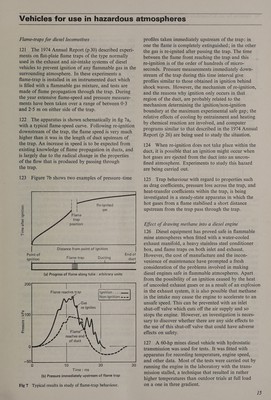

![Flame-traps for diesel locomotives 121 The 1974 Annual Report (p30) described experi- ments on flat-plate flame traps of the type normally used in the exhaust and air-intake systems of diesel vehicles to prevent ignition of any flammable gas in the surrounding atmosphere. In these experiments a flame-trap is installed in an instrumented duct which is filled with a flammable gas mixture, and tests are made of flame propagation through the trap. During the year extensive flame-speed and pressure measure- ments have been taken over a range of between 0-3 and 2:5 m on either side of the trap. 122 The apparatus is shown schematically in fig 7a, with a typical flame-speed curve. Following re-ignition downstream of the trap, the flame speed is very much higher than it was in the length of duct upstream of the trap. An increase in speed is to be expected from existing knowledge of flame propagation in ducts, and is largely due to the radical change in the properties of the flow that is produced by passing through the trap. 123 Figure 7b shows two examples of pressure—time re Re-ignited re) aS gas 5S Flame ro trap = position ® £ kK | Distance from point of ignition | Point of / End of ignition Flame trap Ducting duct (a) Progress of flame along tube : arbitrary units 200 oOo 2100 2 rp] a = - oa Flame reaches end 8 0 —50 (b) Pressure immediately upstream of flame trap Fig 7 Typical results in study of flame-trap behaviour. profiles taken immediately upstream of the trap: in one the flame is completely extinguished; in the other the gas is re-ignited after passing the trap. The time between the flame front reaching the trap and this re-ignition is of the order of hundreds of micro- seconds. Pressure measurements immediately down- stream of the trap during this time interval give profiles similar to those obtained in ignition behind shock waves. However, the mechanism of re-ignition, and the reasons why ignition only occurs in that region of the duct, are probably related to the mechanism determining the ignition/non-ignition boundary at the maximum experimental safe gap; the relative effects of cooling by entrainment and heating by chemical reaction are involved, and computer programs similar to that described in the 1974 Annual Report (p 26) are being used to study the situation. 124 When re-ignition does not take place within the duct, it is possible that an ignition might occur when hot gases are ejected from the duct into an uncon- fined atmosphere. Experiments to study this hazard are being carried out. 125 Trap behaviour with regard to properties such as drag coefficients, pressure loss across the trap, and heat-transfer coefficients within the trap, is being investigated in a steady-state apparatus in which the hot gases from a flame stabilised a short distance upstream from the trap pass through the trap. Effect of drawing methane into a diesel engine 126 Diesel equipment has proved safe in flammable mine atmospheres when fitted with a water-cooled exhaust manifold, a heavy stainless steel conditioner box, and flame traps on both inlet and exhaust. However, the cost of manufacture and the incon- venience of maintenance have prompted a fresh consideration of the problems involved in making diesel engines safe in flammable atmospheres. Apart from the possibility of an ignition caused by the heat of uncooled exhaust gases or as a result of an explosion in the exhaust system, it is also possible that methane in the intake may cause the engine to accelerate to an unsafe speed. This can be prevented with an inlet shut-off valve which cuts off the air supply and so stops the engine. However, an investigation is neces- sary to discover whether there are any side effects to the use of this shut-off valve that could have adverse effects on safety. 127 A 60-hp mines diesel vehicle with hydrostatic transmission was used for tests. It was fitted with apparatus for recording temperature, engine speed, and other data. Most of the tests were carried out by running the engine in the laboratory with the trans- mission stalled, a technique that resulted in rather higher temperatures than outdoor trials at full load on a one in three gradient.](https://iiif.wellcomecollection.org/image/b32222063_0025.jp2/full/800%2C/0/default.jpg)