Specification of Oliver Rice Chase : machinery for the manufacture of medicated and other lozenges.

- Chase, Oliver Rice.

- Date:

- 1855

Licence: Public Domain Mark

Credit: Specification of Oliver Rice Chase : machinery for the manufacture of medicated and other lozenges. Source: Wellcome Collection.

4/16 (page 2)

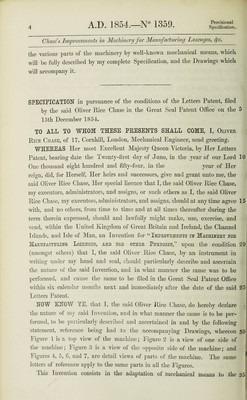

![Chases Improvements in Machinery for Manufacturing Lozenges, Qc. paste to be made are gradually and uniformly brought together, and when formed into a plastic mass rolled out in a continuous strip or sheet ready to be subjected to the action of cutters, which cut out from the sheet the lozenges, cakes, or biscuits it is desired to produce. When the paste has been properly prepared by the mixing apparatus, it is 5 placed in strips of suitable width and length upon an endless apron, which carries it on to a second apron, which delivers it to the cutting cylinder. In passing from the first to the second apron, the paste passes between two revolving belts, which respectively move through compartments containing a suitable dusting powder or flour. This powder is kept from passing out of ] 0 the compartment, and is properly spread over the surface of the dusting belts or aprons by scrapes or blades, placed at a proper inclination just above the surface of the aprons. By this arrangement the surface of the aprons is covered with a thin layer of powder or dusting, which is communicated to the strip of paste as it passes between them on to the second feeding apron. 15 Just before passing from the second feeding apron on to the cutting cylinder, the paste is smoothed or polished by a reciprocating polisher, which is moved back and forth over its surface by means of a crank. Thus polished or smoothed, the paste passes on to the cutter cylinder. This construction and operation of the cylinder is as follows:—It is made 20 of brass or any other proper material, and is perforated with holes of the size and shape of the intended lozenge. These holes are in lines parallel to the axis of the cylinder; screwed into these holes or otherwise attached to the cylinder are tubes or cutters, in which fit pistons attached to piston rods, which pass into the interior of the cylinder. The piston rods have rings on 25 their inner ends, through which pass rods a little longer than the width of the cylinder, in such a manner that all the pistons in one row of tubes or cutters can be simultaneously advanced or retracted by moving the rod passing through their ends. The rods project beyond the end of the cylinder, and are kept up against the head of the cylinder by means of spiral springs, placed 3( one under each end of each rod. When the springs are released, the pistons are on a level with the outer ends or mouths of the tubes or cutters. The pistons are retracted to any desired distance by compressing the spiral springs which support the ends of the rods. This is effected by passing the ends ol the rods under an arc properly adjusted, bv which means the pistons can be 3^ drawn back or thrown out at any point iiff the revolution of the cylinder that may be desired. Over each row of the tubes or cutters projecting from the cylinder is placed](https://iiif.wellcomecollection.org/image/b30752486_0004.jp2/full/800%2C/0/default.jpg)