The large-scale contained use of biological agents / Advisory Committee on Dangerous Pathogens.

- Great Britain. Advisory Committee on Dangerous Pathogens

- Date:

- 1998

Licence: Open Government Licence

Credit: The large-scale contained use of biological agents / Advisory Committee on Dangerous Pathogens. Source: Wellcome Collection.

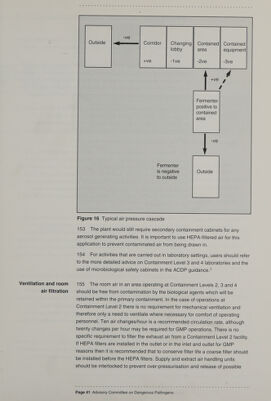

52/68 (page 44)

![Personnel washing arrangements Spillage containment ©, '6 ©) 6) coy eine! fo cols, couid; co) [e/ke. 16: 16) “s) 154 ©) (©) ©, (a) le] sel (6) ou.e8 a) (Wile) b) tel N ele! 16) \p) ite! (ous, elvellge: cepnes (6) en (éy oman an (ence OmPmNen Once) (©: out the tests should wear appropriate protective clothing and masks. Venting of the rooms must be carefully controlled to ensure that persons who may be near the installation are not endangered. If necessary, barriers should be erected in site roadways near the plant until the operation has been successfully completed. 168 Facilities should be provided for washing and decontamination in all Containment Level 2, 3 and 4 process areas. The use of foot, knee or elbow operated taps is recommended in all such installations. 169 Emergency showers and eye wash stations should also be provided for use in an accident involving the contamination of a worker. In an emergency such as this, the worker should call for help in decontamination and should remove all affected clothing while inside the working area. This should then be bagged and autoclaved or incinerated. 170 For operator comfort, showers can be provided for use after normal operations. The requirement for showers as part of the safety and hygiene programme is only mandatory when working at Containment Level 4, though optional at Containment Level 3. 171 The effluents from the sinks and showers must be collected and inactivated before being sent to drain in Containment Level 4 facilities, and preferable for Containment Level 3. 172 While there is no specific requirement for an installation operating with agents in Hazard Group 2 to be designed to contain the entire contents of a fermenter in the event of catastrophic failure, it is considered good practice. If incorporated into the initial building design, this requirement can often be satisfied at little or no additional cost. 173 Containment may be arranged in several ways, either as a bunded area below the fermenter, or as enlarged drain channels under the operating floor or by drainage to a kill tank. 174 In all cases it is important that not only can the spilled contents be satisfactorily inactivated by chemical or heat treatment, but that it is also not possible to move the spillage from the containment area without the deliberate performance of an action designed to do so, for example the starting of a pump. Lines which drain from the bottom of the containment area should be avoided as the isolation valves may be inadvertently left open in which case spillage could be discharged to an effluent system without treatment. Good practice would be to empty the spillage containment area by pumping from above. 175 Besides gross spillage, provision also should be made for minor spillages resulting from, for example, the breakage of glass equipment, an operating error or leakage from a pipe flange or a valve. 7.8). O00, he, © 8) Bie) ©. O86) eh iey 6: 9/6) 6) 6.10) 8h 6, 00) oe) 10: 6a) 6) 60's, colle) eo) /e) (emieus fej lel os euemeMien elon elisale Niel ellouele](https://iiif.wellcomecollection.org/image/b32230163_0052.jp2/full/800%2C/0/default.jpg)