The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

103/1096 page 89

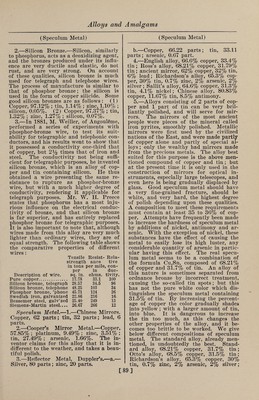

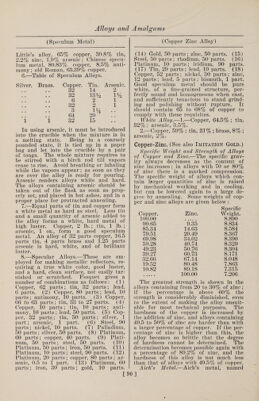

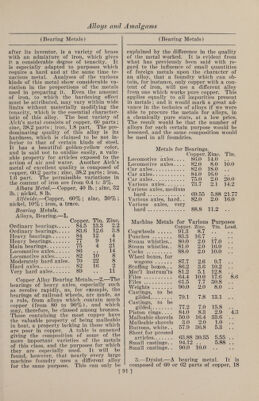

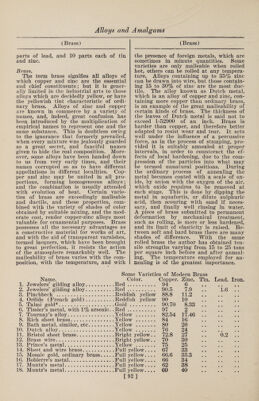

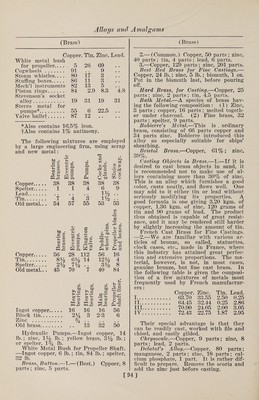

![(Speculum Metal) 2. —Silicon Bronze.—Silicon, similarly to phosphorus, acts as a deoxidizing agent, and the bronzes produced under its influ¬ ence are very ductile and elastic, do not rust, and are very strong. On account of these qualities, silicon bronze is much used for telegraph and telephone wires. The process of manufacture is similar to that of phosphor bronze; the silicon is used in the form of copper silicide. Some good silicon bronzes are as follows: (1) Copper, 97.12% ; tin, 1.14% ; zinc, 1.10% ; silicon, 0.05%. (2) Copper, 97.37% ; tin, 1.32%; zinc, 1.27%; silicon, 0.07%. 3. —In 1881, M. Weiller, of Angouleme, performed a series of experiments with phosphor-bronze wire, to test its suit¬ ability for telegraphic and telephonic con¬ ductors, and his results went to show that it possessed a conductivity one-third that of copper, but 2)4 times that of iron and steel. The conductivity not being suffi¬ cient for telegraphic purposes, he invented silicon bronze, which is an alloy of cop¬ per and tin containing silicon. He thus obtained a wire presenting the same re¬ sistance to rupture as phosphor-bronze wire, but with a much higher degree of conductivity, rendering it applicable for telegraph purposes. Mr. W. H. Preece states that phosphorus has a most inju¬ rious influence on the electrical conduc¬ tivity of bronze, and that silicon bronze is far superior, and has entirely replaced phosphor bronze for telegraphic purposes. It is also important to note that, although wires made from this alloy are very much lighter than ordinary wires, they are of equal strength. The following table shows the comparative properties of different wires: Tensile Resist- Rela- strength ance tive in tons per mile, con- per in due- Description of wire. sq. in. ohms. tivity, Pure copper. 17.78 33.1 100 Silicon bronze, telegraph 28.57 34.5 96 Silicon bronze, telephone Phosphor bronze, ’phone 48.25 103 34 45.71 124 26 Swedish iron, galvanized 22.86 216 16 Bessemer steel, galv’zed 25.40 249 13 Siemens-Martin steel.... 26.67 266 12 Speculum Metal.—1.—Chinese Mirrors. Copper, 62 parts; tin, 32 parts; lead, 6 parts. 2. —Cooper’s Mirror Metal.—Copper, 57.85% ; platinum, 9.49% ; zinc, 3.51% ; tin, 27.49%; arsenic, 1.66%. The in¬ ventor claims for this alloy that it is in¬ different to the weather, and takes a beau¬ tiful polish. 3. —Reflector Metal, Duppler’s.—a.— Silver, 80 parts; zinc, 20 parts. (Speculum Metal) b.—Copper, 66.22 parts; tin, 33.11 parts; arsenic, 0.67 part. 4. —English alloy, 66.6% copper, 33.4% tin; Ross’s alloy, 68.21% copper, 31.79% tin; ancient mirror, 62% copper, 32% tin, 6% lead; Richardson’s alloy, 65.3% cop¬ per, 30% tin, 0.7% zinc, 2% arsenic, 2% silver; Sallit’s alloy, 64.6% copper, 31.3% tin, 4.1% nickel; Chinese alloy, 80.83% copper, 11.67% tin, 8.5% antimony. 5. —Alloys consisting of 2 parts of cop¬ per and 1 part of tin can be very bril¬ liantly polished, and will serve for mir¬ rors. The mirrors of the most ancient people were pieces of the mineral called iron pyrites, smoothly polished. Metallic mirrors were first used by the civilized nations of the East, and were made partly of copper alone and partly of special al¬ loys ; only the wealthy had mirrors made from the precious metals. The alloy best suited for this purpose is the above men¬ tioned compound of copper and tin ; but at the present time it is only used in the construction of mirrors for optical in¬ struments, especially large telescopes, and even here is being gradually displaced by glass. Good speculum metal should have a very fine-grained fracture, should be white, and very hard, the highest degree of polish depending upon these qualities. A composition to meet these requirements must contain at least 35 to 36% of cop¬ per. Attempts have frequently been made to increase the hardness of speculum metal by additions of nickel, antimony and ar¬ senic. With the exception of nickel, these substances have the effect of causing the metal to easily lose its high luster, any considerable quantity of arsenic in partic¬ ular having this effect. The real specu¬ lum metal seems to be a combination of the formula Cu4Sn, composed of 68.21% of copper and 31.7% of tin. An alloy of this nature is sometimes separated from ordnance bronze by incorrect treatment, causing the so-called tin spots; but this has not the pure white color which dis¬ tinguishes the speculum metal containing 31.5% of tin. By increasing the percent¬ age of copper the color gradually shades into yellow ; with a larger amount of tin, into blue. It is dangerous to increase the tin too much, as this changes the other properties of the alloy, and it be¬ comes too brittle to be worked. We give below different compositions of speculum metal. The standard alloy, already men¬ tioned, is undoubtedly the best. Stand¬ ard alloy, 68.21% copper, 31.7% tin; Otto’s alloy, 68.5% copper, 31.5% tin; Richardson’s alloy, 65.3% copper, 30% tin, 0.7% zinc, 2% arsenic, 2% silver; [89]](https://iiif.wellcomecollection.org/image/b31361523_0103.jp2/full/800%2C/0/default.jpg)