The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

109/1096 page 95

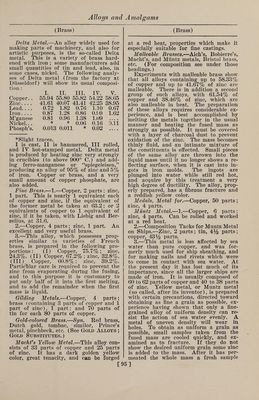

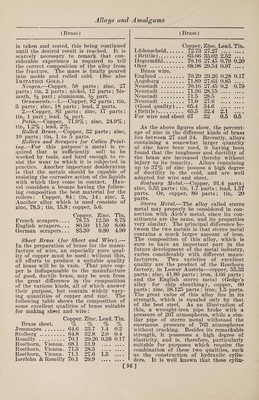

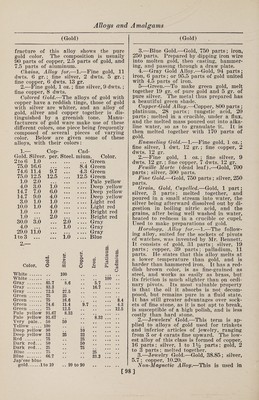

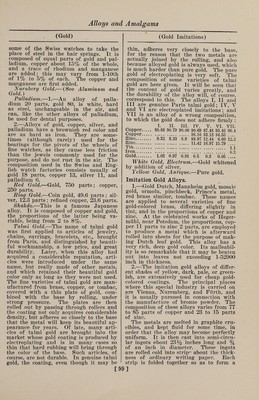

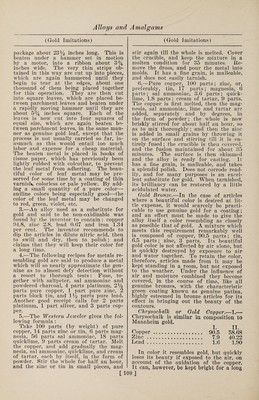

![Delta Metal.—An alloy widely used for making parts of machinery, and also for artistic purposes, is the so-called Delta metal. This is a variety of brass hard¬ ened with iron ; some manufacturers add small quantities of tin and lead, also, in some cases, nickel. The following analy¬ ses of Delta metal (from the factory at Diisseldorf) will show its usual composi¬ tion : I. II. III. IV. V. Copper. . 55.94 55.80 55.82 54.22 58.65 Zinc... . 41.61 40.07 41.41 42.25 38.95 Lead.. .. 0.72 1.82 0.76 1.10 0.67 Iron. .. . 0.87 1.28 0.86 0.99 1.62 M’ganese 0.81 0.96 1.38 1.09 • • • • Nickel.. . * ❖ 0.06 0.16 9.11 Phosph’s. 0.013 0.011 * 0.02 • • •» • * Slight traces. I is cast, II is hammered, III rolled, and IV hot-stamped metal. Delta metal is produced by heating zinc very strongly in crucibles (to above 900° C.) and add¬ ing ferro-manganese or “spiegeleisen,” producing an alloy of 95% of zinc and 5% of iron. Copper or brass, and a very small amount of copper phosphate, are also added. Fine Brass.—1.—Copper, 2 parts ; zinc, 1 part. This is nearly 1 equivalent each of copper and zinc, if the equivalent of the former metal be taken at 63.2; or 2 equivalents of copper to 1 equivalent of zinc, if it be taken, with Liebig and Ber¬ zelius, at 31.6. 2. —Copper, 4 parts ; zinc, 1 part. An excellent and very useful brass. 3. —This alloy, which possesses prop¬ erties similar to varieties of French brass, is prepared in the following pro¬ portions : (I) Copper, 75.7%; zinc, 24.3%. (II) Copper, 67.2%; zinc, 32.8%. (Ill) Copper, 60.8%; zinc, 39.2%. Particular care is required to prevent the zinc from evaporating during the fusing, and to this purpose it is customary to put only half of it into the first melting, and to add the remainder when the first mass is liquid. Gilding Metals.—Copper, 4 parts; brass (containing 3 parts of copper and 1 part of zinc), 1 part; and 70 parts of tin for each 80 parts of copper. Gold-colored Brass.—Syn. Red brass, Dutch gold, tombac, • similor, Prince’s metal, pinchbeck, etc. (See Gold Alloys ; Gold Substitutes.) Macht’s Yellow Metal.—This alloy con¬ sists of 33 parts of copper and 25 parts of zinc. It has a dark golden yellow color, great tenacity, and can be forged at a red heat, properties which make it especially suitable for fine castings. Malleable Brasses.—Aich’s, Bobierre’s, Macht’s, and Muntz metals, Bristol brass, etc. (For composition see under those headings.) Experiments with malleable brass show that all alloys containing up to 58.33% of copper and up to 41.67% of zinc are malleable. There is in addition a second group of such alloys, with 61.54% of copper and 38.46% of zinc, which are also malleable in heat. The preparation of these alloys requires considerable ex¬ perience, and is best accomplished by melting the metals together in the usual manner and heating the fused mass as strongly as possible. It must be covered with a layer of charcoal dust to prevent oxidation of the zinc. The mass becomes thinly fluid, and an intimate mixture of the constituents is effected. Small pieces of the same alloy are thrown into the liquid mass until it no longer shows a re¬ flecting surface, when it is cast into in¬ gots in iron molds. The ingots are plunged into water while still red hot, and acquire by this treatment a very high degree of ductility. The alloy, prop¬ erly prepared, has a fibrous fracture and a reddish yellow color. Medals, Metal for.—Copper, 50 parts; zinc, 4 parts. Muntz Metal.—1.—Copper, 6 parts ; zinc, 4 parts. Can be rolled and worked at a red heat. 2. —Composition Tacks for Muntz Metal on Ships.—Zinc, 2 parts; tin, 4% parts ; copper, 43% parts. 3. —This metal is less affected by sea water than pure copper, and was for¬ merly much used for ship sheathing, and for making nails and rivets which were to come in contact with sea water. At the present day it has lost much of its importance, since all the larger ships are made of iron. It is usually composed of 60 to 62 parts of copper and 40 to 38 parts of zinc. Yellow metal, or Muntz metal (so called, after its inventor), is prepared with certain precautions, directed toward obtaining as fine a grain as possible, ex¬ perience having shown that only a fine¬ grained alloy of uniform density can re¬ sist the action of sea water evenly. A metal of uneven density will wear in holes. To obtain as uniform a grain as possible, small samples taken from the fused mass are cooled quickly, and ex¬ amined as to fracture. If they do not show the desired uniform grain some zinc is added to the mass. After it has per¬ meated the whole mass a fresh sample [95]](https://iiif.wellcomecollection.org/image/b31361523_0109.jp2/full/800%2C/0/default.jpg)