The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

110/1096 page 96

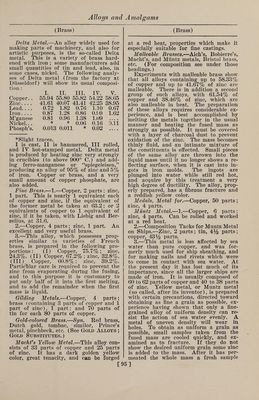

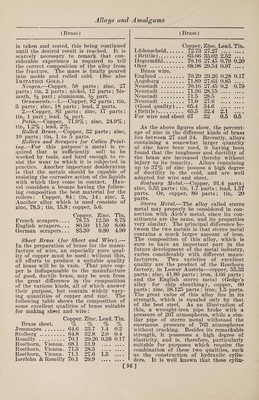

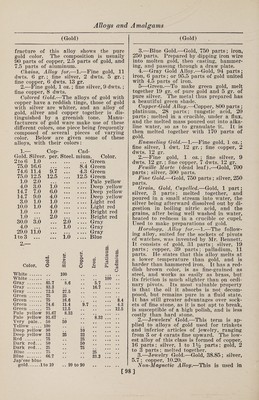

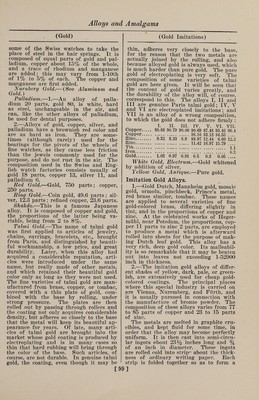

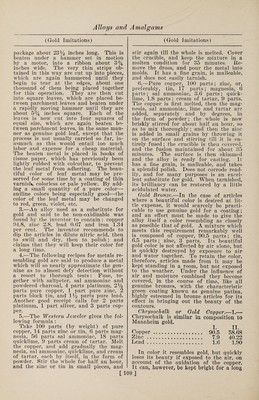

![(Brass) is taken and tested, this being continued until the desired result is reached. It is scarcely necessary to remark that con¬ siderable experience is required to tell the correct composition of the alloy from the fracture. The mass is finally poured into molds and rolled cold. (See also Imitation Gold.) Ncogen.—Copper, 58 parts ; zinc, 27 parts; tin, 2 parts ; nickel, 12 parts; ‘bis¬ muth, Yq part; aluminum, % part. Ornaments.—1.—Copper, 82 parts ; tin, 3 parts; zinc, 18 parts ; lead, 2 parts. 2.—Copper, 83 parts; zinc, 17 parts ; tin, 1 part; lead, % part. Potin.—Copper, 71.9% ; zinc, 24.9% ; tin, 1.2% ; lead, 2%. Rolled Brass.—Copper, 32 parts; zinc, 10 parts ; tin, 1 to 5 parts. Rollers and Scrapers for Calico Print¬ ing.—For this purpose a metal is re¬ quired that is sufficiently soft to be worked by tools, and hard enough to re¬ sist the wear to which it is subjected in practice. Another important desideratum is that the metals should be capable of resisting the corrosive action of the liquids with which they come in contact. Hau- vel considers a bronze having the follow¬ ing composition the best material for the rollers: Copper, 84; tin, 14; zinc, 2. Another alloy which is used consists of zinc, 78.5; tin, 15.8; copper, 5.6. Copper. Zinc. Tin. French scrapers.... 78.75 12.50 8.75 English scrapers.... 80.50 11.50 8.00 German scrapers... 85.30 9.80 4.90 Sheet Brass (for Sheet and Wire).— In the preparation of brass for the manu¬ facture of wire, an especially pure qual¬ ity of copper must be used; without this, all efforts to produce a suitable quality of brass will be in vain. That pure cop¬ per is indispensable to the manufacture of good, ductile brass, may be seen from the great difference in the composition of the various kinds, all of which answer their purpose, but contain widely vary¬ ing quantities of copper and zinc. The following table shows the composition of some excellent qualities of brass suitable for making sheet and wire: Copper. Zinc. Lead. Tin. Brass sheet. % % % % Jemmapes. 64.6 33.7 1.4 0.2 Stolberg. 64.8 32.8 2.0 0.4 Romillv. 70.1 29.26 0.38 0.17 Rosthorn, Vienna. 68.1 31.9 • • • • • • • • Rosthorn, Vienna. 71.5 28.5 • * • • • • • • Rosthorn, Vienna. 71.1 27.6 1.3 • • • • Iserlohn & Romilly 70.1 29.9 • • *> • • • • • (Brass) Liidenscheid. .. . Copper, . . 72.73 Zinc. Lead. 27.27 .... Tin. • • • • (Brittle). .. 63.66 33.02 2.52 • • • • Ilegermiihl. .. 70.16 27.45 0.79 0.20 Oker. .. 68.98 29.54 0.97 • • • • Brass wire. England. .. 70.29 29.26 0.28 0.17 Augsburg. .. 71.89 27.63 0.85 • • • • Neustadt. .. 70.16 27.45 0.2 0.79 Neustadt. . . 71.36 28.15 • e • o • • • • Neustadt ...... .. 71.5 28.5 » • • • • • • • Neustadt. .. 71.0 27.6 • • • • • • » • (Good quality). .. 65.4 34.6 • • • • • • • • (Brittle). . . 65.5 32.4 2.1 • • • • For wire and sheet 67 32 0.5 0.5 As the above figures show, the percent¬ age of zinc in the different kinds of brass lies between 27 and 34. Recently, alloys containing a somewhat larger quantity of zinc have been used, it having been found that the toughness and ductility of the brass are increased thereby without injury to its tenacity. Alloys containing up to 37% of zinc possess a high degree of ductility in the cold, and are well adapted for wire and sheet. Statuary Metal.—Copper, 91.4 parts ; zinc, 5.53 parts ; tin, 1.7 parts ; lead, 1.37 parts. Or, copper, 80 parts; tin, 20 parts. Sterro Metal.—The alloy called sterro metal may properly be considered in con¬ nection with Aich’s metal, since its con¬ stituents are the same, and its properties very similar. The principal difference be¬ tween the two metals is that sterro metal contains a much larger amount of iron. The composition of this alloy, which is sure to have an important part in the future development of the metal industry, varies considerably with different manu¬ facturers. Two varieties of excellent quality are the product of the Rosthorn factory, in Lower Austria—copper, 55.33 parts ; zinc, 41.80 parts ; iron, 4.66 parts ; and the English sterro metal (Gedge’s alloy for ship sheathing), copper, 60 parts; zinc, 38.125 parts ; iron, 1.5 parts. The great value of this alloy lies in its strength, which is equaled only by that of the best steel. As an illustration of this, a wrought-iron pipe broke with a pressure of 267 atmospheres, while a sim¬ ilar pipe of sterro metal withstood the enormous pressure of 763 atmospheres without cracking. Besides its remarkable strength, it possesses a high degree of elasticity, and is, therefore, particularly suitable for purposes which require the combination of these two qualities, such as the construction of hydraulic cylin¬ ders. It is well known that these cylin- [96]](https://iiif.wellcomecollection.org/image/b31361523_0110.jp2/full/800%2C/0/default.jpg)