The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

118/1096 page 104

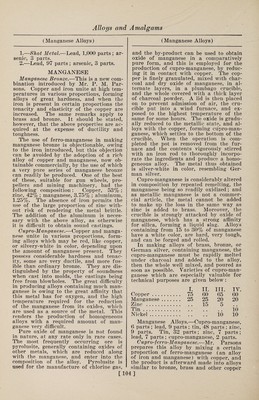

![(Manganese Alloys) 1. —Shot Metal.—Lead, 1,000 parts ; ar¬ senic, 3 parts. 2. —Lead, 97 parts; arsenic, 3 parts. MANGANESE Manganese Bronze.—This is a new com¬ bination introduced by Mr. P. M. Par¬ sons. Copper and iron unite at high tem¬ peratures in various proportions, forming alloys of great hardness, and when the iron is present in certain proportions the tenacity and elasticity of the copper are increased. The same remarks apply to brass and bronze. It should be stated, however, that the above properties are ac¬ quired at the expense of ductility and toughness. The use of ferro-manganese in making manganese bronze is objectionable, owing to the iron introduced, but this objection can be avoided by the adoption of a rich alloy of copper and manganese, now ob¬ tainable commercially, by the use of which a very pure series of manganese bronze can readily be produced. One of the best of these, suitable for gun wheels, pro¬ pellers and mining machinery, had the following composition : Copper, 53% ; zinc, 42% ; manganese, 3.75% ; aluminum, 1.25%. The absence of iron permits the use of the large proportion of zinc with¬ out risk of rendering the metal brittle. The addition of the aluminum is neces¬ sary with the above alloy, as otherwise it is difficult to obtain sound castings. Cupro-Manganese.—Copper and manga¬ nese unite in various proportions, form¬ ing alloys which may be red, like copper, or silvery-white in color, depending upon the amount of manganese present. They possess considerable hardness and tenac¬ ity, some are very ductile, and more fus¬ ible than ordinary bronze. They are dis¬ tinguished by the property of soundness when cast into molds, the castings being free from blowholes. The great difficulty in producing alloys containing much man¬ ganese is owing to the great affinity that this metal has for oxygen, and the high temperature required for the reduction of the manganese from its oxides, which are used as a source of the metal. This renders the production of homogeneous alloys with a required amount of man¬ ganese very difficult. Pure oxide of manganese is not found in nature, at any rate only in rare cases. The most frequently occurring ore is pyrolusite, generally containing oxides of other metals, which are reduced along with the manganese, and enter into the. composition of the alloy. Pyrolusite is used for the manufacture of chlorine gas, (Manganese Alloys) and the by-product can be used to obtain oxide of manganese in a comparatively pure form, and this is employed for the production of cupro-manganese, by reduc¬ ing it in contact with copper. The cop¬ per is finely granulated, mixed with char¬ coal and dry oxide of manganese, in al¬ ternate layers, in a plumbago crucible, and the whole covered with a thick layer of charcoal powder. A lid is then placed on to prevent admission of air, the cru¬ cible put into a wind furnace, and ex¬ posed to the highest temperature of the same for some hours. The oxide is gradu¬ ally reduced to the metallic state, and al¬ loys with the copper, forming cupro-man¬ ganese, which settles to the bottom of the crucible. When the operation is com¬ pleted the pot is removed from the fur¬ nace and the contents vigorously stirred with an iron rod to thoroughly incorpo¬ rate the ingredients and produce a homo¬ geneous alloy. The metal thus obtained is silver-white in color, resembling Ger¬ man silver. Cupro-manganese is considerably altered in composition by repeated remelting, the manganese being so readily oxidized ; and as metallic manganese is not a commer¬ cial article, the metal cannot be added to make up the loss in the same way as zinc is added to brass. Moreover, the crucible is strongly attacked by oxide of manganese, which has a strong affinity for silica, forming a liquid slag. Alloys containing from 15 to 30% of manganese have a white color, are hard, very tough, and can be forged and rolled. In making alloys of brass, bronze, or German silver, containing manganese, the cupro-manganese must be rapidly melted under charcoal and added to the alloy, then the whole well mixed, and poured as soon as possible. Varieties of cupro-man¬ ganese which are especially valuable for technical purposes are given below : I. II. III. IV. Copper . .. . 75 60 65 60 Manganese .... .. . 25 25 20 20 Zinc . 15 5 Tin .. • • ' 10 Nickel. • • io 10 Manganese Alloys.—Cupro-manganese, 6 parts ; lead, 9 parts; tin, 48 parts ; zinc, 9 parts. Tin, 32 parts; zinc, 7 parts; lead, 7 parts ; cupro-manganese, 2 parts. Gupro-f err o-Manganese.—Mr. Parsons prepares this alloy by mixing a certain proportion of ferro-manganese (an alloy of iron and manganese) with copper, and the product is afterward made into alloys similar to bronze, brass and other copper [104]](https://iiif.wellcomecollection.org/image/b31361523_0118.jp2/full/800%2C/0/default.jpg)