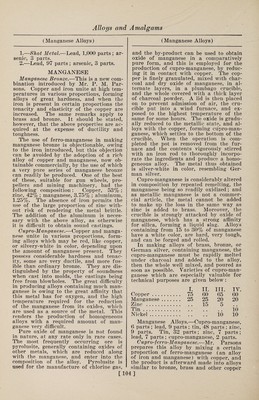

The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

119/1096 page 105

![(Manganese Alloys) (Platinum Alloys) alloys. The ferro-manganese and the cop¬ per are melted in separate crucibles, and the ferro alloy added to the copper. The effect of this combination is similar to that produced by the addition of ferro¬ manganese to the decarburized iron in the Bessemer converter. The manganese and iron in the metallic state, having a great affinity for oxygen, cleanse the copper of any oxides it may contain, by combining with the oxygen, and rising to the sur¬ face, in the form of slag, and thus render the metal dense and homogeneous. A por¬ tion of the iron and manganese is util¬ ized in this manner, and the remainder becomes permanently combined with the copper, and plays an important part in improving and modifying the quality of the bronze and brass alloys, afterward prepared from the copper thus treated. The effect is greatly to increase their strength, hardness and toughness, the de¬ grees of all of which can be modified at will, according to the quantity of ferro¬ manganese used and the proportions of iron and manganese it contains. An alloy of 40 parts of copper and 60 parts of ferro-manganese, with a suitable quantity of some appropriate flux, produces a metal of such tenacity that it surpasses the best steel armor plates. The melted mixture is cast in blocks, and is perfectly malle¬ able. To obtain a white metal that can be rolled out in sheets, the above alloy is melted again, and 20 or 25% of zinc or white metal added, which imparts to it the desired quality. A plate of the first named alloy, 2 in. thick, was found, by experiment, to offer more resistance to a cannon ball than a steel armor plate of the same thickness. This new kind of “white bronze” is not to be confounded with the alloy used under the same name for gravestones and monuments, and which consists principally of zinc. Experiments have been made in Paris with a new alloy having a white color, yet containing no nickel. It is said to be very strong and malleable. It is made of copper and ferro-manganese, the pro¬ portions being varied according to the purpose for which the alloy is to be em¬ ployed. Manganese German Silver.—1.—“Man¬ ganese German silver” was made from copper, 70 parts; manganese, 15 parts; zinc, 15 parts. But as this alloy proved rather brittle in the rollers, the propor¬ tions were altered to copper, 80 parts; manganese, 15 parts; zinc, 5 parts ; when a beautiful white and ductile metal was obtained, which would take a high polish. 2.—An excellent substitute for German silver can be obtained, having the follow¬ ing composition : Copper, 67.25% ; man¬ ganese, 18.50% ; zinc, 13% ; aluminum, 1.25%. The metal thus produced is said to be as strong as German silver, and makes better castings, while it is less liable to corrosion. Its electrical resist¬ ance is four times as great as that of the older alloy. Manganese Steel.—Copper, 80% ; man¬ ganese, 15% ; zinc, 5%. Manganese and Tin.—Manganese and tin combine as readily as manganese and copper. Tin, however, shows, as in or¬ dinary bronzes, a tendency to separate itself in the middle of thick castings from the other alloys, because it remains long¬ est in a fluid condition, and under the process of solidification it seems to get squeezed out of those parts of a casting which retain the heat longest. Manganese-Tin Bronze.—An important series of experiments made at Isabelle- Pliitte have shown that the strongest “manganese-tin bronze” is obtained by al¬ loying 85% of copper with 6% of tin, 5% of zinc and 5% of manganese copper, so that the cooled product retains something above 1% of manganese. The best mode of procedure is first to melt the copper in a crucible, then to add, successively, tin and zinc, but manganese copper only at the last moment, when the metals are well stirred up with a rod made from gas-retort graphite; a reaction upon the oxides of the metallic bath is clearly no¬ ticed, as it begins to boil and emit sparks after the addition of manganese, of which a portion is carried into the slag uManganese Tin and Zinc Bronzes” are obtained by adding to an alloy of copper, tin and zinc, a certain quantity of “man¬ ganese copper,” viz.: the combination of 70 parts of copper with 30 parts of man¬ ganese, as above described, by which an increase of at least 9% of strength is obtained over the ordinary alloy. This seems to be greatly due, as in the case of the refined, tough copper, to a chemi¬ cal action of the manganese ; for all or¬ dinary bronzes contain more or less of copper and tin oxides, which are reduced to metal by the action of the manganese. An addition of manganese seems, how¬ ever, to have also physically a strengthen¬ ing effect, and an addition of 3 to 6% of manganese copper has been experimen¬ tally found to suit the purpose best. PLATINUM Platinum Bronze.—Several alloys of platinum, of a comparatively inexpensive nature, have been manufactured under the [105]](https://iiif.wellcomecollection.org/image/b31361523_0119.jp2/full/800%2C/0/default.jpg)