The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

130/1096 page 116

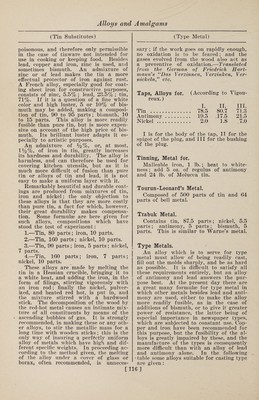

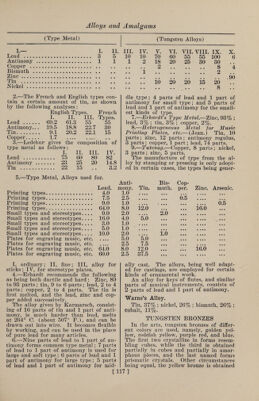

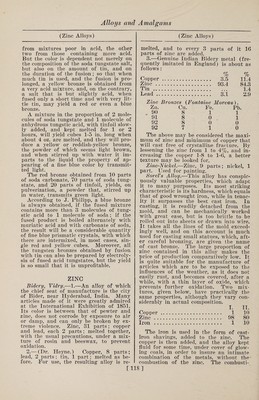

![(Tin Substitutes) poisonous, and therefore only permissible in the case of tinware not intended for use in cooking or keeping food. Besides lead, copper and iron, zinc is used, and sometimes bismuth. An admixture of zinc or of lead makes the tin a more effectual protector of iron against rust. A French alloy, especially good for coat¬ ing sheet iron for constructive purposes, consists of zinc, 5.5% ; lead, 23.5% ; tin, 71%. If it is a question of a fine white color and high luster, 5 or 10% of bis¬ muth may be added, making a composi¬ tion of tin, 90 to 95 parts ; bismuth, 10 to 15 parts. This alloy is more readily fusible than pure tin, but is more expen¬ sive on account of the high price of bis¬ muth. Its brilliant luster adapts it es¬ pecially to artistic purposes. An admixture of %%, or, at most, 1)4%, of iron in tin, greatly increases its hardness and durability. The alloy is harmless, and can therefore be used for covering kitchen utensils, but as it is much more difficult of fusion than pure tin or alloys of tin and lead, it is not easy to make a uniform layer with it. Remarkably beautiful and durable coat¬ ings are produced from mixtures of tin, iron and nickel; the only objection to these alloys is that they are more costly than pure tin, a fact for which, however, their great durability makes compensa¬ tion. Some formulae are here given for such alloys, compositions which have stood the test of experiment: 1. —Tin, 80 parts; iron, 10 parts. 2. —Tin, 160 parts; nickel, 10 parts. 3. —Tin, 90 parts ; iron, 5 parts ; nickel, 7 parts. 4. —Tin, 160 parts; iron, 7 parts; nickel, 10 parts. These alloys are made by melting the tin in a Hessian crucible, bringing it to a white heat, and adding the iron, in the form of filings, stirring vigorously with an iron rod; finally the nickel, pulver¬ ized, and heated red hot, is put in, and the mixture stirred with a hardwood stick. The decomposition of the wood by the red-hot metal causes an intimate mix¬ ture of all constituents by means of the ascending bubbles of gas. It is strongly recommended, in making these or any oth¬ er alloys, to stir the metallic mass for a long time with wooden sticks; this is the only way of insuring a perfectly uniform alloy of metals which have high and dif¬ ferent specific weights. In proceeding ac¬ cording to the method given, the melting of the alloy under a cover of glass or borax, often recommended, is unneces¬ (Type Metal) sary ; if the work goes on rapidly enough, no oxidation is to be feared; and the gases evolved from the wood also act as a preventive of oxidation.—Translated from the German of Friedrich Hart¬ mann's “Das Verzinnen, Verzinlcen, Ver- nickeln,” etc. Taps, Alloys for. (According to Vigou- reux.) I. II. III. Tin .. 78.5 80.7 71.3 Antimony. 19.5 .17.5 21.5 Nickel . 2.0 1.8 7.0 I is for the body of the tap, II for the spigot of the plug, and III for the bushing of the plug. Tinning, Metal for. Malleable iron, 1 lb.; heat to white¬ ness ; add 5 oz. of regulus of antimony and 24 lb. of Molucca tin. Tourun-Leonard’s Metal. Composed of 500 parts of tin and 64 parts of bell metal. Trabuk Metal. Contains tin, 87.5 parts; nickel, 5.5 parts; antimony, 5 parts; bismuth, 5 parts. This is similar to Warne’s metal. Type Metals. An alloy which is to serve for type metal must allow of being readily cast, fill out the molds sharply, and be as hard as possible. It is difficult to satisfy all these requirements entirely, but an alloy of antimony and lead answers the pur¬ pose best. At the present day there are a great many formulae for type metal in which other metals besides lead and anti¬ mony are used, either to make the alloy more readily fusible, as in the case of additions of bismuth, or to give if greater power of resistance, the latter being of especial importance in newspaper types, which are subjected to constant use. Cop¬ per and iron have been recommended for this purpose, but the fusibility of the al¬ loys is greatly impaired by these, and the manufacture of the types is consequently more difficult than with an alloy of lead and antimony alone. In the following •table some alloys suitable for casting type are given : [116]](https://iiif.wellcomecollection.org/image/b31361523_0130.jp2/full/800%2C/0/default.jpg)