The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

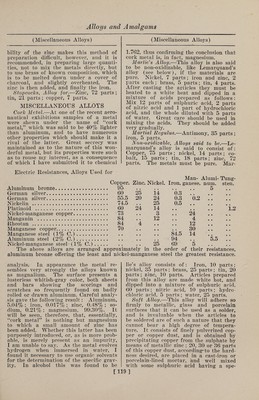

133/1096 page 119

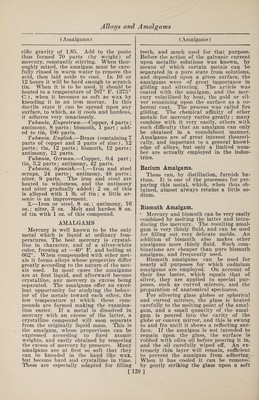

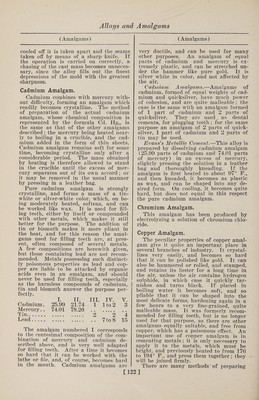

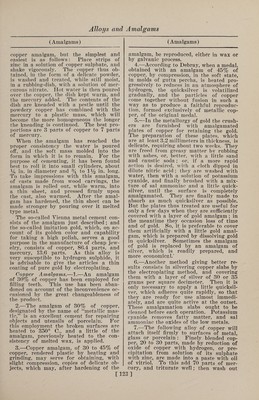

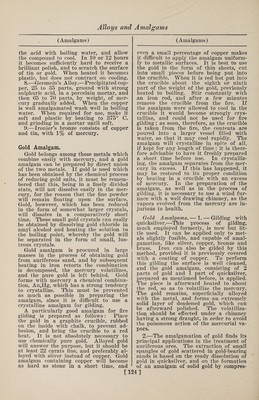

![(Miscellaneous Alloys) (Miscellaneous Alloys) bility of the zinc makes this method of preparation difficult, however, and it is recommended, in preparing large quanti¬ ties, not to mix the metals directly, but to use brass of known composition, which is to be melted down under a cover of charcoal, and slightly overheated. The zinc is then added, and finally the iron. Stopcocks, Alloy for.—Zinc, 72 parts; tin, 21 parts ; copper, 7 parts. MISCELLANEOUS ALLOYS Cork Metal.—At one of the recent aero¬ nautical exhibitions samples of a metal were shown under the name of “cork metal,” which was said to be 40% lighter than aluminum, and to have numerous other properties which should make it a rival of the latter. Great secrecy was maintained as to the nature of this won¬ derful metal, but its properties were such as to rouse my interest, as a consequence of which I have submitted it to chemical Electric Resistances, Alloys Used for 1.762, thus confirming the conclusion that cork metal is, in fact, magnesium. Marlie’s Alloy.—This alloy is also said to be non-oxidizable, like Lemarquand’s alloy (see below), if the materials are pure. Nickel, 7 parts; iron and zinc, 2 parts each ; brass, 5 parts ; tin, 4 parts. After casting the articles they must be heated to a white heat and dipped in a mixture of acids prepared as follows: Mix 12 parts of sulphuric acid, 2 parts of nitric acid and 1 part of hydrochloric acid, and the whole diluted with 5 parts of water. Great care should be used in mixing the acids. They should be added very gradually. Martial Regulus.—Antimony, 35 parts ; iron, 5 parts. Non-oxidizable, Alloys said to he.—Le¬ marquand’s alloy is said to consist of: Copper, 75 parts; nickel, 14 parts; co¬ balt, 15 parts; tin, 18 parts; zinc, 72 parts. The metals must be pure. Mar- Aluminum bronze. Copper. .. 95 Zinc. Nickel. i—i . '-j • p Man- Alumi- Tung- ganese. num. sten. 5 German silver. 60 25 ii 0.3 • • German silver. 55.5 20 24 0.3 0.2 .. Nickelin . 74.5 • • 25 0.5 • • • • » • Platinoid . 60 24 14 1.2 Nickel-manganese copper. .. 73 • • 3 24 Manganin . .. 84 • • 12 4 Rheotan ... 84 4 • • 12 Manganese copper. . . 70 • • • • 30 Manganese steel (1% C.). • • • • 84.5 14 Aluminum steel (2% C.). • • • • 94 • • 0*0 • • Nickel-manganese steel - (1% C.) . . e • 25 69 5 The above alloys are arranged approximately in the order of their resistances, aluminum bronze offering the least and nickel-manganese steel the greatest resistance. analysis. In appearance the metal re¬ sembles very strongly the alloys known as magnalium. The surface presents a lusterless whitish-gray color, both sheets and bars showing the scorings and scratches so frequently found on badly rolled or drawn aluminum. Careful analy¬ sis gave the following result: Aluminum, 5.04% ; iron, 0.017% ; zinc, 0.48% ; so¬ dium, 0.21% ; magnesium, 99.30%. It will be seen, therefore, that, essentially, “cork metal” is nothing but magnesium to which a small amount of zinc has been added. Whether this latter has been purposely introduced, or, as is more prob¬ able, is merely present as an impurity, I am unable to say. As the metal evolves hydrogen when immersed in water, I found it necessary to use organic solvents for the determination of the specific grav¬ ity. In alcohol this was found to be lie’s alloy consists of: Iron, 10 parts; nickel, 35 parts; brass, 25 parts ; tin, 20 parts ; zinc, 10 parts. Articles prepared from this alloy are made white hot, and dipped into a mixture of sulphuric acid, 60 parts; nitric acid, 10 parts; hydro¬ chloric acid, 5 parts ; water, 25 parts. Soft Alloy.—This alloy will adhere so firmly to metallic, glass and porcelain surfaces that it can be used as a solder, and is invaluable when the articles to be soldered are of such a nature that they cannot bear a high degree of tempera¬ ture. It consists of finely pulverized cop¬ per or copper dust, and is obtained by precipitating copper from the sulphate by means of metallic zinc ; 20, 30 or 36 parts of this copper dust, according-to the hard¬ ness desired, are placed in a cast-iron or porcelain-lined mortar, and well mixed with some sulphuric acid having a spe- [119]](https://iiif.wellcomecollection.org/image/b31361523_0133.jp2/full/800%2C/0/default.jpg)