The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

137/1096 page 123

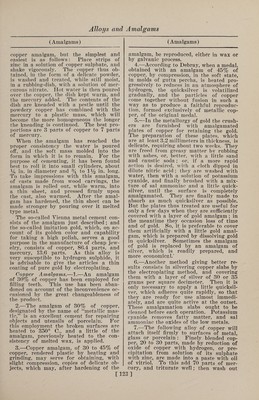

![(Amalgams) copper amalgam, but the simplest and easiest is as follows: Place strips of zinc in a solution of copper sulphate, and shake vigorously. The copper thus ob¬ tained, in the form of a delicate powder, is washed and treated, while still moist, in a rubbing-dish, with a solution of mer¬ curous nitrate. Hot water is then poured over the copper, the dish kept warm, and the mercury added. The contents of the dish are kneaded with a pestle until the powdery copper has combined with the mercury to a plastic mass, which will become the more homogeneous the longer the kneading is continued. The best pro¬ portions are 3 parts of copper to 7 parts of mercury. When the amalgam has reached the proper consistency the water is poured off, and the soft mass molded into the form in which it is to remain. For the purpose of cementing, it has been found best to roll it into small cylinders, about y8 in. in diameter and % to 1)4 in. long. To take impressions with this amalgam, of casts made from wood carvings, the amalgam is rolled out, while warm, into a thin sheet, and pressed firmly upon the cast, also warmed. After the amal¬ gam has hardened, the thin sheet can be made stronger by pouring over it melted type metal. The so-called Vienna metal cement con¬ sists of the amalgam just described ; and the so-called imitation gold, which, on ac¬ count of its golden color and capability for taking a high polish, serves a good purpose in the manufacture of cheap jew¬ elry, consists of copper, 86.4 parts, and mercury, 13.6 parts. As this alloy is very susceptible to hydrogen sulphide, it is advisable to give the articles a thin coating of pure gold by electroplating. Copper Amalgams.—1.—An amalgam of 30% of copper has been employed for filling teeth. This use has been aban¬ doned on account of the inconvenience oc¬ casioned by the great changeableness of the product. 2. —The amalgam of 30% of copper, designated by the name of “metallic mas¬ tic,” is an excellent cement for repairing objects and utensils of porcelain. For this employment the broken surfaces are heated to 350° C., and a little of the amalgam, previously heated to the con¬ sistency of melted wax, is applied. 3. —Copper amalgam, of 30 to 45% of copper, rendered plastic by heating and grinding, may serve for obtaining, with slight compression, copies of delicate ob¬ jects, which may, after hardening of the (Amalgams) amalgam, be reproduced, either in wax or by galvanic process. 4. —According to Debray, when a medal, obtained with an amalgam of 45% of copper, by compression, in the soft state, in molds of gutta percha, is heated pro¬ gressively to redness in an atmosphere of hydrogen, the quicksilver is volatilized gradually, and the particles of copper come together without fusion in such a way as to produce a faithful reproduc¬ tion.. formed exclusively of metallic cop¬ per, of the original medal. 5. —In the metallurgy of gold the crush¬ ers are furnished with amalgamated plates of copper for retaining the gold. The preparation of these plates, which are at least 3.2 millimeters in thickness, is delicate, requiring about two weeks. They are freed from greasy matter bv rubbing with ashes, or, better, with a little sand and caustic soda; or, if a more rapid action is desired, with a cloth dipped in dilute nitric acid ; they are washed with water, then with a solution of potassium cyanide, and finally brushed with a mix¬ ture of sal ammoniac and a little quick¬ silver, until the surface is completely amalgamated. They are finally made to absorb as much quicksilver as possible. But the plates thus treated are useful for only a few days when they are sufficiently covered with a layer of gold amalgam ; in the meantime they occasion loss of time and of gold. So, it is preferable to cover them artificially with a little gold amal¬ gam, which is prepared by dissolving gold in quicksilver. Sometimes the amalgam of gold is replaced by an amalgam of silver, which is readily prepared, and more economical.' 6. —Another method giving better re¬ sults consists in silvering copper slabs by the electroplating method, and covering them with a layer of silver of 30 or 35 grams per square decimeter. Then it is only necessary to apply a little quicksil¬ ver, which adheres quite rapidly, so that they are ready for use almost immedi¬ ately, and are quite active at the outset. These amalgamation slabs ought to be cleaned before each operation. Potassium cyanide removes fatty matter, and sal ammoniac the oxides of the low metals. 7. —The following alloy of copper will attach itself firmly to surfaces of metal, glass or porcelain : Finely blended cop¬ per, 20 to 30 parts, made by reduction of oxide of copper with hydrogen, or pre¬ cipitation from solution of its sulphate with zinc, are made into a paste with oil of vitriol. To this add 70 parts of mer¬ cury, and triturate well; then wash out [123]](https://iiif.wellcomecollection.org/image/b31361523_0137.jp2/full/800%2C/0/default.jpg)