The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

90/1096 page 76

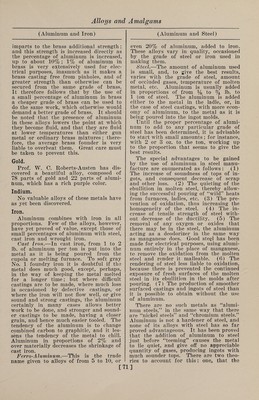

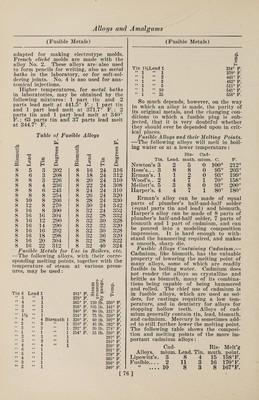

![(Fusible Metals) (Fusible Metals) adapted for making electrotype molds. French cliche molds are made with the alloy No. 2. These alloys are also used to form pencils for writing, also as metal baths in the laboratory, or for soft-sol¬ dering joints. No. 4 is aso used for ana¬ tomical injections. Higher temperatures, for metal baths in laboratories, may be obtained by the following mixtures: 1 part tin and 2 parts lead melt at 441.5° F.; 1 part tin and 1 part lead melt at 371.7° F.; 2 parts tin and 1 part lead melt at 340° F.; 63 parts tin and 37 parts lead melt at 344.7° F. Table of Fusible Alloys fa fa Xi 4-> 3 m CD CD -M 3 m <D CD a T5 u a r3 L-i m 03 3 CD m c3 3 fcJO © M w fa EH A S fa EH Q 8 5 3 202 8 16 24 316 8 6 3 208 8 18 24 312 8 8 3 226 8 20 24 310 8 8 4 236 8 22 24 308 8 8 6 243 8 24 24 310 8 8 8 254 8 26 24 320 8 10 8 266 8 28 24 330 8 12 8 270 8 30 24 342 8 16 8 300 8 32 24 352 8 16 16 304 8 32 28 332 8 16 12 290 8 32 30 328 8 16 14 290 8 32 32 320 8 16 16 292 8 32 30 328 8 16 18 298 8 32 36 320 8 16 20 304 8 32 38 322 8 16 22 312 8 32 40 324 Fusible Metals for TJse in Boilers, etc. —The following alloys, with their corre¬ sponding melting points, together with the temperature of steam at various press¬ ures, may be used : © CP d & w z © co p a Tin 6 Lead 1 381° F. *-> © 6C Mh. © EH < < 5 ‘ 1 3-78° F. Q. >> Xi < < 4 * 1 365° F. 120 lb. 350° < < 3 ‘ 1 356° F. 105 lb. 341° i < 2 ‘ 1 340° F. 90 lb. 331° i ( 1 % ‘ 1 334° F. 75 lb. 320° < < 4 ‘ 4 Bismuth 1 320° F. 60 lb. 307° t < 3 ‘ 3 i i 1 310° F. 45 lb. 282° < i 2 ‘ 2 < i 1 292° F. 30 lb. 274° t i 1 * 1 i i 1 254° F. 15 lb. 250° t i 2 ‘ 2 t i 1 292° i i 3 ‘ 3 * i 1 310° ( t 4 ‘ 4 it 1 320° < ( 6 ‘ 1 381° < i 5 * 1 378° i i 4 ‘ 1 365° i i 3 ‘ 1 356° it 2 ‘ 1 340° F. F. F. F. F. F. F. F. F. F. F. F. F. F. F. F. Tin l^Lead 1 “1 “ 1 “1 “2 “1 “3 “1 “5 “ 1 “ 10 “ 1 “ 25 d a © Eh 334° F. 370° F. 441° F. 482° F. 511° F. 541° F. 558° F. So much depends, however, on the way in which an alloy is made, the purity of its original metals, and the changing con¬ ditions to which a fusible plug is sub¬ jected, that it is very doubtful whether they should ever be depended upon in crit¬ ical places. Fusible Alloys and their Melting Points. -—The following alloys will melt in boil¬ ing water or at a lower temperature: Bis- Cad- Tin. Lead. muth. mium. c. F. Newton’s 3 2 5 0 100° 212 Rose’s.. . 3 8 8 0 95° 203 Erman’s. 1 1 2 0 93° 199 Wood’s.. 2 4 7 1 70° 158 Mellott’s. 5 3 8 0 93° 200 Harper’s. 4 4 7 1 80° 180 Erman’s alloy can be made of equal parts of plumber’s half-and-half solder (equal parts tin and lead) and bismuth. Harper’s alloy can be made of 8 parts of plumber’s half-and-half solder, 7 parts of bismuth and 1 part of cadmium, and can be poured into a modeling composition impression. It is hard enough to with¬ stand the hammering required, and makes a smooth, sharp die. Fusible Alloys Containing Cadmium.— Cadmium, like bismuth, has the valuable property of lowering the melting point of many alloys, some of which are readily fusible in boiling water. Cadmium does not render the alloys so crystalline and brittle as bismuth, many of its combina¬ tions being capable of being hammered and rolled. The chief use of cadmium is in fusible alloys, which are used as sol¬ ders, for castings requiring a low tem¬ perature, and in dentistry for alloys for stopping hollow teeth. Alloys of cad¬ mium generally contain tin, lead, bismuth, and cadmium. Mercury is sometimes add¬ ed to still further lower the melting point. The following table shows the composi¬ tion and melting points of the more im¬ portant cadmium alloys : Cad- Bis- Melt’g Alloys, mium. Lead. Tin. muth. point. Lipowitz’s. 3 8 4 15 158°F. Fusible.... 2 11 3 16 170° F. “ 10 8 3 8 167° F. [76]](https://iiif.wellcomecollection.org/image/b31361523_0090.jp2/full/800%2C/0/default.jpg)