The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

91/1096 page 77

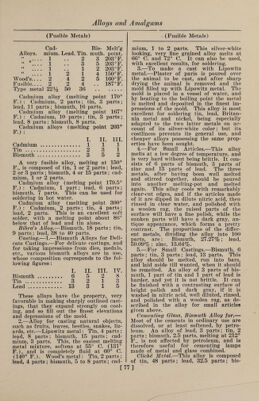

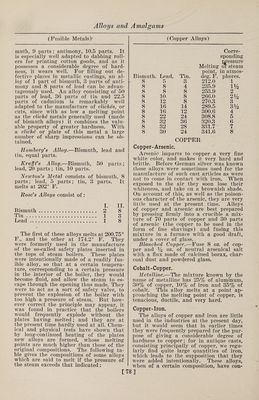

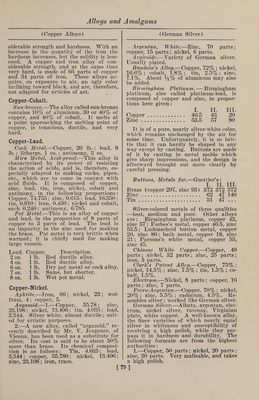

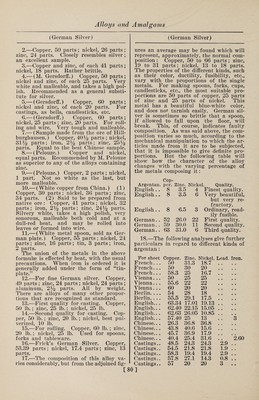

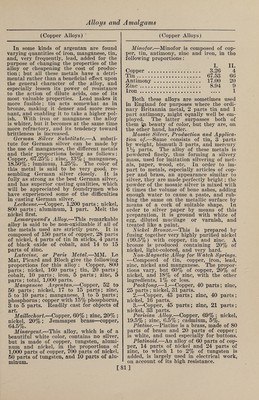

![(Fusible Metals) Cad- Bis- Melt’g Alloys, mium. Lead. Tin. muth. point. Wood’s Fusible 1 1 1 1 2 2 2 4 2 Type metal 22% 50 2 3 1 1 2 4 36 3 5 2 4 5 203°F. 203 °F. 203°F. 150°F. 160° F. 187 °F. Cadmium alloy (melting point 170° F.) : Cadmium, 2 parts; tin, 3 parts; lead, 11 parts ; bismuth, 16 parts. Cadmium alloy (melting point 167° F.) : Cadmium, 10 parts; tin, 3 parts; lead, 8 parts ; bismuth, 8 parts. Cadmium alloys (melting point 203° F.) : I. II. III. Cadmium . 1 1 1 Tin . 2 3 1 Bismuth. 3 5 2 A very fusible alloy, melting at 150° F., is composed of tin, 1 or 2 parts; lead, 2 or 3 parts ; bismuth, 4 or 15 parts; cad¬ mium, 1 or 2 parts. Cadmium alloy (melting point 179.5° F.) : Cadmium, 1 part; lead, 6 parts; bismuth, 7 parts. This can be used for soldering in hot water. Cadmium alloy (melting point 300° F.) : Cadmium, 2 parts; tin, 4 parts; lead, 2 parts. This is an excellent soft solder, with a melting point about 86° below that of lead and tin alone. Bibra's Alloy.—Bismuth, 18 parts; tin, 9 parts ; lead, 38 to 40 parts. Casting.—1.—Bismuth Alloys for Deli¬ cate Castings.—For delicate castings, and for taking impressions from dies, medals, etc., various bismuth alloys are in use, whose composition corresponds to the fol¬ lowing figures: Bismuth Tin Lead ... I. 6 3 13 II. 5 2 3 III. 2 1 1 IV. 8 3 5 These alloys have the property, very favorable in making sharply outlined cast¬ ings, that they expand strongly on cool¬ ing, and so fill out the finest elevations and depressions of the mold. 2.—Alloy for casting natural objects, such as fruits, leaves, beetles, snakes, liz¬ ards, etc.—Lipowitz metal: Tin, 4 parts : lead, 8 parts; bismuth, 15 parts; cad¬ mium, 3 parts. This, the easiest melting metal mixture, softens at 55° C. (131° F.), and is completely fluid at 60° C. (140° F.). Wood’s metal: Tin, 2 parts ; lead, 4 parts; bismuth, 5 to 8 parts; cad- c (Fusible Metals) mium, 1 to 2 parts. This silver-white looking, very fine grained alloy melts at 66° C. and 72° C. It can also be used, with excellent results, for soldering. 3. —To make a cast with Lipowitz metal.—Plaster of paris is poured over the animal to be cast, and after sharp drying the animal is removed and the mold filled up with Lipowitz metal. The mold is placed in a vessel of water, and by heating to the boiling point the metal is melted and deposited in the finest im¬ pressions of the mold. This alloy is most excellent for soldering tin, lead, Britan¬ nia metal and nickel, being especially adapted to the two latter metals on ac¬ count of its silver-white color; but its costliness prevents its general use, and cheaper alloys possessing the same prop¬ erties have been sought. 4. —For Small Articles.—This alloy melts at a low degree of temperature, and is very hard without being brittle. It con¬ sists of 6 parts of bismuth, 3 parts of zinc and 13 parts of lead. The three metals, after having been well melted and stirred together, should be poured into another melting-pot and melted again. 'This alloy cools with remarkably clear-cut edges, and if the articles made of it are dipped in dilute nitric acid, then rinsed in clear water, and polished with a woolen rag, the raised parts of the surface will have a fine polish, while the sunken parts will have a dark gray, an¬ tique appearance, which forms a pretty contrast. The proportions of the differ¬ ent metals, dividing the alloy into 100 parts, are: Bismuth, 27.27%; lead, 59.09%; zinc, 13.64%. 5. —For Small Castings.—Bismuth, 6 parts; tin, 3 parts ; lead, 13 parts. This alloy should be melted, run into bars, and laid aside till wanted, when it should be remelted. An alloy of 3 parts of bis¬ muth, 1 part of tin and 1 part of lead is harder, and yet it is not brittle. It can be finished with a contrasting surface of bright polish and dark gray, if it is washed in nitric acid, well diluted, rinsed, and polished with a woolen rag, as de¬ scribed in the alloy for small articles given above. Cementing Class, Bismuth Alloy for.— Most of the cements in ordinary use are dissolved, or at least softened, by petro¬ leum. An alloy of lead, 3 parts; tin, 2 parts; bismuth, 2.5 parts, melting at 212° F., is not affected by petroleum, and is therefore useful for cementing lamps made of metal and glass combined. Cliche Metal.—This alloy is composed of tin, 48 parts; lead, 32.5 parts; bis- 77]](https://iiif.wellcomecollection.org/image/b31361523_0091.jp2/full/800%2C/0/default.jpg)