The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

97/1096 page 83

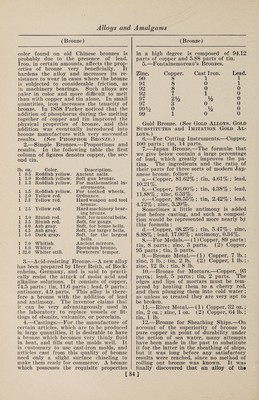

![(Bronze) parts of tin, and unite the two metals by frequently stirring the mass. Product very fine. 4. —Copper, 3 parts; tin, 1 part, as above. Some of the finest church bells in the world have this composition. 5. —Copper, 72 parts; tin, 26% parts; iron, 1% parts. The bells of small clocks or pendules are made of this alloy in Paris. 6. —Bell Metal, Fine.—Copper, 71 parts ; tin, 26 parts ; zinc, 2 parts; iron, 1 part. 7. —Bell Metal, for Large Bells.—Cop¬ per, 100 lb. ; tin, from 20 to 25 lb. 8. —Bell Metal, for Small .Bells.—Cop¬ per, 3 lb. ; tin, 1 lb. 9. —Alloys for Cymbals and Gongs.—• Copper, 100 parts, with about 25 parts of tin. To give this compound the sono¬ rous property in the highest degree, the piece should be ignited after it is cast, and then plunged immediately into cold water. 10. —Alloy for Tam-tams or Gongs.—- Copper, 80 parts; tin, 20 parts; ham¬ mered out, with frequent annealing. An alloy of 78% of copper and 22% of tin answers better and can be rolled out. 11. —Kara Kane Bell Metal.—The Jap¬ anese, who are great bronze workers, add lead, zinc and iron to their bell metal, with wonderful effect. Their name for these compounds is kara kane. The fol¬ lowing are the proportions they use : First quality, 60 parts copper, 24 parts tin, 9 parts zinc, 3 parts iron ; second quality, 60 parts copper, 15 parts tin, 3 parts zinc, 8 parts lead; third quality, 60 parts cop¬ per, 18 parts tin, 6 parts zinc, 12 parts lead, 3 parts iron. For small bells they employ the first quality, and for large bells the third quality. 12. —Silver Bell Metal.—This alloy, used for small bells, has a very beautiful silvery tone, and is nearly white in ■color. It is made in three varieties: (1) Cop¬ per, 40% ; tin, 60%. (2) Copper, 41.5% ; tin, 58.5%. (3) Copper, 41.7%; tin, 58.4%. Large bells are cast in loam molds, the design or ornamentation of the bell being given by the shape of the mold, and perfected by chasing after it has cooled. Small bells are usually cast in sand molds, though at the present time iron molds are frequently employed. 13. —Algiers metal is also used for small hand bells. (See Tin Alloys.) Bronze.—1.—The term “bronze” is usu¬ ally applied to all alloys consisting chiefly of copper and tin. These metals have been known from very remote times, and the importance of the mixture of copper (Bronze) and tin appears to have been among the first discoveries of the metallurgists. It is remarkable for the exactness of the impressions which it takes by molding, as well as its durability; hence, exten¬ sively employed in. the casting of busts, medals and statues. Bell, cannon, and speculum metal are varieties of bronze. In ancient times, when the manufacture of steel was ill understood, cutting in¬ struments were frequently made of this alloy. For statuary work the great de¬ sideratum is to obtain an alloy capable of flowing freely into the most minute outlines of the mold, hard, and yet tough, and capable of resisting the corroding ac¬ tion of the weather. It must also acquire that peculiar antique green appearance that is so much admired in bronzes. When only a small quantity of the alloy is required it is prepared in crucibles, but for statues or larger works, on reverbera¬ tory hearths. The fusion of the mixed metals must be conducted under pounded charcoal, and as rapidly as possible. When melted it must be frequently stirred to¬ gether, to produce a perfect mixture, be¬ fore casting. Coal is the fuel principally employed for the furnaces. The great fea¬ ture of modern bronzes is the substitution of triple and quadruple alloys for the old dual alloys. French bronzes nearly always contain the four metals, copper, tin, lead and zinc, and in some cases small quanti¬ ties of nickel, arsenic, antimony and sul¬ phur. Each of these elements exerts an influence on bronze in proportion to the amount present, and if such influence is prejudicial for certain uses care must be taken in the selection of the metals em¬ ployed for admixture. Impure copper is by no means a rarity in commerce, and may contain ingredients fatal to the prop¬ erties of certain varieties of bronze. The difficulty of preparing alloys of definite composition is increased when scrap is remelted with new metal, unless great care is taken to keep scrap of a given quality separate from other varieties: such old metal is also liable to contain iron and other foreign metals mechani¬ cally mixed with it. Zinc, in small quan¬ tity, added to copper and tin, often has a beneficial influence, as in casting, for instance, the metal runs thinner, fills upon the molds, and is freer from pin¬ holes. Lead alloys very imperfectly with bronze, showing a great tendency to liquate out on cooling, the greater portion being found in the lower part of the cast¬ ing. A small quantity of lead is said to make the alloy more malleable and denser. The peculiar patina of a velvety black [83]](https://iiif.wellcomecollection.org/image/b31361523_0097.jp2/full/800%2C/0/default.jpg)