The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins.

- Albert A. Hopkins

- Date:

- 1910

Licence: Public Domain Mark

Credit: The Scientific American cyclopedia of formulas : partly based upon the twenty-eighth edition of Scientific American cyclopedia of receipts, notes and queries 15,000 formulas / edited by Albert A. Hopkins. Source: Wellcome Collection.

98/1096 page 84

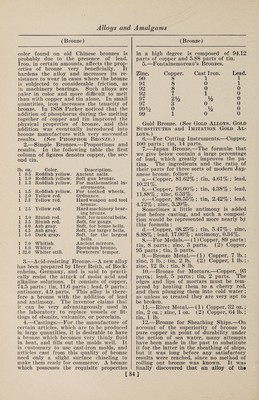

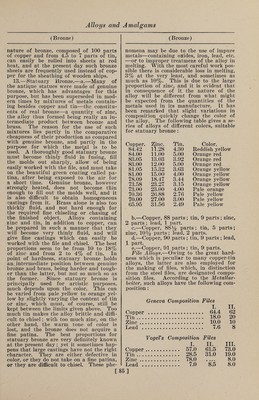

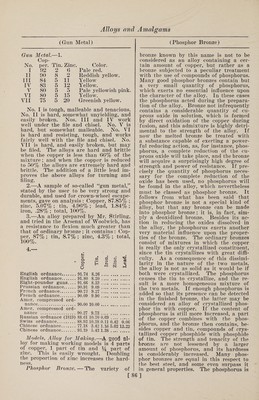

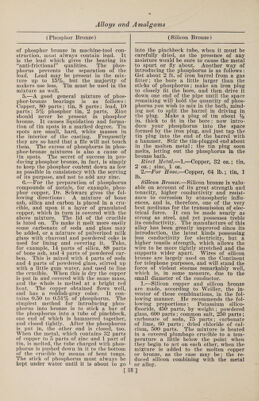

![color found on old Chinese bronzes is probably due to the presence of lead. Iron, in certain amounts, affects the prop¬ erties of bronze very beneficially. It hardens the alloy and increases its re¬ sistance to wear in cases where the bronze is subjected to considerable friction, as in machinery bearings. Such alloys are paler in color and more difficult to melt than with copper and tin alone. In small quantities, iron increases the tenacity of bronze. In 1858 Parker noticed that the addition of phosphorus during the melting together of copper and tin improved the physical properties of bronze, and this addition was eventually introduced into bronze manufacture with very successful results. (See Phosphor Bronze.) 2.—Simple Bronzes.—Proportions and results. In the following table the first column of figures denotes copper, the sec¬ ond tin. lb. oz. Color. Description. 1 0.5 Reddish yellow. Ancient nails. 1 1.0 Reddish yellow. Soft gun bronze. 1 1.3 Reddish yellow. For mathematical in¬ struments. 1 1.5 Reddish yellow. For toothed wheels. 1 2.0 Yellow red. Ordnance. 1 2.3 Yellow red. Hard weapon and tool bronze. 1 2:5 Yellow red. Hard machinery bear¬ ing bronze. 1 3.0 Bluish red. Soft, for musical bells. 1 3.5 Bluish red. Soft, for gongs. 1 4.0 Ash gray. Soft, for house bells. 1 4.5 Ash gray. Soft, for larger bells. 1 5.0 Dark gray. Soft, for the largest bells. 1 7.0 Whitish. Ancient mirrors. 1 8.0 Whiter. Speculum bronze. 1 32.0 Whiter still. Pewterers' temper. 3.— -Acid-resisting Bronze.—A new alloy has been prepared by Herr Reith, of Bock- enheim, Germany, and is said to practi¬ cally resist the attack of moist acid and alkaline solutions. It consists of copper, 74.5 parts ; tin, 11.6 parts ; lead, 9 parts ; antimony, 4.9 parts. This alloy is there¬ fore a bronze with the addition of lead and antimony. The inventor claims that it can be very advantageously used in the laboratory to replace vessels or fit¬ tings of ebonite, vulcanite, or porcelain. 4.—Castings.^-For the manufacture of certain articles, which are to be produced in large quantities, it is desirable to have a bronze which becomes very thinly fluid in heat, and fills out the molds well. It is customary to use cast-iron molds, and articles cast from this quality of bronze need only a slight surface chiseling to make them ready for commerce. A bronze which possesses the requisite properties in a high degree is composed of 94.12 parts of copper and 5.88 parts of tin. 5.— -Fontainemoreau’s Bronzes. Zinc. Copper. Cast Iron. Lead. 90 8 1 1 91 8 0 1 92 8 0 0 92 7 1 0 97 21/2 y2 0 97 3 0 0 991/2 0 % 0 99 1 0 0 Gold Bronze. (See Gold Alloys, Gold Substitutes and Imitation Gold Al¬ loys.) 6. —For Cutting Instruments.—Copper, 100 parts ; tin, 14 parts. 7. —Japan Bronze.—The formulae that we give below contain a large percentage of lead, which greatly improves the pa¬ tina. The ingredients and the ratio of their parts for three sorts of modern Jap¬ anese bronze, follow : a. —Copper, 81.62% ; tin, 4.61% ; lead, 10.21%. b. —Copper, 76.60% ; tin, 4.38% ; lead, 11.88% ; zinc, 6.53%. c. —Copper, 88.55% ; tin, 2.42% ; lead, 4.72% ; zinc, 3.20%. Sometimes a little antimony is added just before casting, and such a composi¬ tion would be represented more nearly by this formula: d. —Copper, 68.25%; tin, 5.47%; zinc, 8.88% ; lead, 17.06% ; antimony, 0.34%. 8. —For Medals.— (1) Copper, 89 parts ; tin, 8 parts; zinc, 3 parts. (2) Copper, 95 parts ; tin, 5 parts. 9. —Bronze Metal.— (1) Copper, 7 lb.; zinc, 3 lb.; tin, 2 lb. (2) Copper, 1 lb.; zinc, 12 lb.; tin, 8 lb. 10. —Bronze for Mortars.—Copper, 93 parts; lead, 5 parts; tin, 2 parts. The edges and lips of mortars must be tem¬ pered by heating them to a cherry red, and then plunging them into cold water; as unless so treated they are very apt to be broken. 11. —Rivet Metal.— (1) Copper, 32 oz.; tin, 2 oz.; zinc, 1 oz. (2) Copper, 64 lb.; tin, 1 lb. 12. —Bronze for Sheathing Ships.—On account of the superiority of bronze to pure copper in point of durability under the action of sea water, many attempts have been made in the past to substitute it for the latter in the sheathing of ships, but it was long before any satisfactory results were reached, since no method of rolling out bronze was known. It was finally discovered that an alloy of th« [84]](https://iiif.wellcomecollection.org/image/b31361523_0098.jp2/full/800%2C/0/default.jpg)