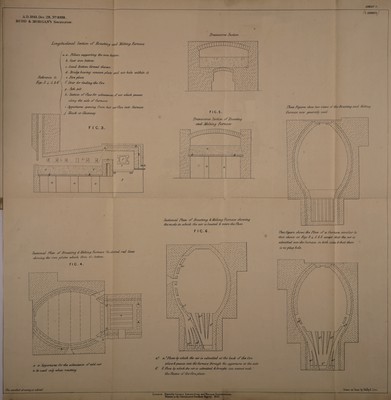

Specification of Edward Budd and William Morgan : furnaces for the reduction of copper and other ores."

- Budd, Edward.

- Date:

- 1855

Licence: Public Domain Mark

Credit: Specification of Edward Budd and William Morgan : furnaces for the reduction of copper and other ores.". Source: Wellcome Collection.

15/16 (page 9)

![]3udd and Morgans Improvements in Furnaces, is added, and is similarly treated, when the bottom is complete, and the furnace is ready for the first small charge of copper or metal, which is usually given to season the bottom. To keep the iron plates constantly cool, a flue communi¬ cating with the excavation under the furnace passes up the solid mass of 5 masonry in the front corner of the furnace opposite the stack through which the rarefied air passes with great rapidity from beneath, by which means a current of cold air is constantly brought in contact with the external surface of the iron plates on which the bottom is supported. From the iron plates being thus kept constantly at a moderate temperature, the sand bottom placed 10 on it absorbs only a very trifling quantity of the copper or copper metal com¬ posing the charge in the furnace, as it (the copper or metal) is cooled and solidified before it can reach the iron plates. The saving thereby occasioned in interest of capital and expcnce of breaking up the bottoms of furnaces is very great. 15 Ilavin g thus described the nature of our Invention, we would remark that we do not confine ourselves to the precise details herein described, so long as the peculiar character of either part of our Invention be retained; and we are aware that reverberatory furnaces suitable for other manufactures than copper have had heated air introduced at the bridges and other parts thereof; and 20 we mention this circumstance in order to state that we do not claim the intro¬ duction of heated air into reverberatory furnaces generally, nor do we claim the so-constructing reverberatory furnaces as to heat air before passing into the same when uncombined with the process of oxydising copper ore or zinc ore; and we are also aware that reverberatory furnaces have before been made 25 with cast iron bottoms when used in other processes than that of melting copper; and we are informed that a small experimental furnace for melting copper was, before the date of our Patent, made and used with an iron bottom, but without any provision for cooling the said iron bottom, which would be inapplicable to large furnaces used for practical purposes; and we 30 mention these in order to say that we do not claim the use of iron bottoms to furnaces unless combined with the melting of copper, and so arranged as to allow of air or other fluid passing below to cool the same. And we would wish it to be understood that what we claim is,— First, the application of air heated before it enters the furnace where copper 35 or zinc ore is being calcined, or copper or copper metal is being roasted, by passing air near to or in contact with suitably arranged heated flues or wavs. Secondly, wo claim calcining of copper or zinc ore and the roasting of copper or copper metal in reverberatory furnaces, so arranged as to have air introduced and heated by flues formed in the bridge, sides, or other parts of the furnace.](https://iiif.wellcomecollection.org/image/b3074233x_0015.jp2/full/800%2C/0/default.jpg)