Improvement to Palmer's endless self-computing scale and key : adapting it to the different professions, with examples and illustrations for each profession, and also to colleges, academies and schools : with a time telegraph making, by uniting the two, a computing telegraph / by John E. Fuller.

- Fuller, John E. (John Emery), 1799-1878

- Date:

- 1851

Licence: Public Domain Mark

Credit: Improvement to Palmer's endless self-computing scale and key : adapting it to the different professions, with examples and illustrations for each profession, and also to colleges, academies and schools : with a time telegraph making, by uniting the two, a computing telegraph / by John E. Fuller. Source: Wellcome Collection.

Provider: This material has been provided by the National Library of Medicine (U.S.), through the Medical Heritage Library. The original may be consulted at the National Library of Medicine (U.S.)

12/16

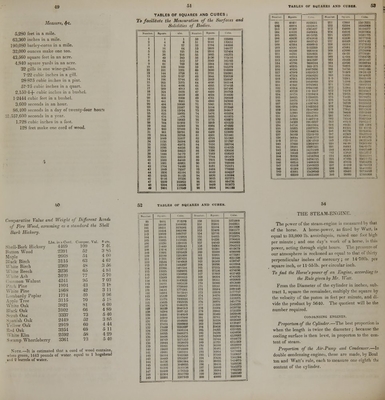

![55 Velocity of the Piston loproduce the best effect.—In engines working the steam expansively, 100 times the square root of the length of the stroke in feet, is the best velocity in feet per minute. (n engines not working expansively, 103 times the square root of the length of the stroke in feet, is the best velocity in feet per minute. To find the quantity of Water required for Steam md Injection.—Multiply the area of the cylinder in feet, by half the velocity in feet for single, and by the whole velocity in feet for double engines. Add l-10th for cooling and waste ; and this, divided by 1497 (at 11non pressure on the valve of 2lb. per circular inch), wil give the quantity of water required for steam per minute. The quantity of water for injection should be 24 times that required for steam. The diameter of the injection-pipe should be l-36th part of that of the cylinder. The valves should be as large as practicable. The boiler should be capable of evaporating abou 12 gallons per hour for each horse power. NON-CONDENSING, OR HIGH PRESSURE ENGINES. The length of the cylinder should be at least twice i's diameter. The velocity of the piston, in feet per minute, should be 103 times the square root of the length of the stroke MARINE ENGINES. The construction and arrangement of the Marine Steam Engine necessarily differ from that of the ordi- nary condensing Engine, on account of the peculiar form of the floating structure in which it is placed, and of the absence of that solid support which can be ob- tained for Engines on land. The importance of ef fecting economy of room and weight on board a steam- vessel, has led to the adoption of various methods of communicating motion to the paddle wheels; and vertical, oscillating, and other varieties of Engine have been introduced, with more or less success; but the more general form is that of the beam or lever Engine, the position of the beam being reversed on being plac- ed on each side of the bottom of the cylinder. The arrangement of the condenser, air-pump, &c, is also necessarily accommodated to the space in which the machinery is required to be fixed. The following Dimensions are given by Mr. Rus- sell, for the Cylinders of Marine Engines of various power: For 10 horse power, 20 inches diameter, 2 ft. 0 in. stroke, .. 20 .. 17 .. 2 ft. 6 in. .. .. 30 .. 32 .. 3 ft. 2 in. .. .. 40 .. 35 .. 3ft.6in. .. .. 50 .. 40 .. 4 ft. 0 in. .. g | nil rati hi | SofEipe. I da nirein \t- spberea. .! Waier. i- ' iiMini mini | ... = 1 fdbyl = I . IW.-I I,, .r J C'li L5i 2|33h 30m 3 32li 30m 7.1 13.8212.57 \.i% 3 1902.15 11111.59 3.5 2..r>f> .38 I . 1469.5|7822.23 |3.5 2.73 1.24 Friction of Steam-engines. The - loss of power by friction, between beam and direct action engines is found by experiment to be so to be unnecessary to be taken into account in estimating their relative advantages. The amount ef pressure upon the piston, expended in each kind of i iming friction appears, on an average, to be not more than about 1 lb. to the square inch, in well-constructed engiucs. Steam-engines for Cotton and Paper Mills. For Cotton Mills.—The best steam-engines for cot. ton-mills are ihe double-acting, working the steam expansively. The most advantageous mean pressure i ton with low pressure si ir circu- lar inch, and each circular inch will suffice to drive lindles of cotton yarn twist with the machinery. For mule yarn, add 15 to the number of the yarn, and multiply the sum by-26; the II be the numbi r of spindli i for each circular inch of piston. Or, one hot power will drive 100 spindles with cotton yarn, and machinery. And for mule yarn, add 56 in feet; or 100 times, if the steam is worked expan- sively. The area of the cylinder should be, to the area of the steam-passages, as 4800 is to the velocity of the piston, found as above. Form and Direction of Steam-pipes.—Enlargements in steam-pipes succeeded by contractions, always re- tard the velocity of the steam—more or less according to the nature of the contraction—and the like effect is produced by bends and angles in the pipes. These should therefore be made as straight, and their internal surface as uniform and free from inequalities as may be practicable. The following proportions of velocity, from Mr. Tredgold, will exemplify this :— The velocity of motion that would result from the direct unretarded action of the column of fluid which produces it, being unity .... 1000 or 8 The velocity through an aperture in a thin plate by the same pressure is .625 or 5 Through a tube from two to three diame- ters in length, projecting outwards .813 or 6.5 Through a tube of the same length, pro- jecting inwards ... .681 or 5.45 Through a conical tube, or mouth-piece, of the form of the contracted vein .983 or 7.9 58 For60 horse power, 43 inches diameter, 4 ft. 3 in. stroke. .. 70 .. 46 .. 4ft.6in. .. .. 80 .. 49 .. 4ft. 9in. .. .. 90 .. 52 .. 5ft.Oia. .. ..100 .. 55 .. 5 ft. 6 in. .. ..125 .. 59 .. 6 ft. 0 in. .. ..150 .. 62 .. 6ft.3in. .. ..175 .. 66 .. 6ft. 6in. .. ..200 .. 70 .. 7ft.0in. .. .250 .. 76 .. 7 ft. 6 in. .. ..300 .. 82 .. 8 ft. 0 in. .. ..350 .. 87 .. 8ft.6in. .. ..400 .. 92 .. 9ft.2in. .. ..500 .. 100 .. lOft.Oin. .. Economy of Steam-jackets. The following Table presents the results of three experiments made in France to ascertain the economy of steam-jackets to the cylinders of Engines, in the consumption of fuel. In the 1st, the steam first enter- ed the jacket round the cylinder, and passed from thence into the cylinder. In the 2nd, the steam enter- ed the cylinder directly, without passing into the jacket. In the 3rd, the steam entered both the cylinder and jacket directly, by means of separate communications between them and the boiler. The result shows an increase in the consumption of fuel of nearly five- sevenths, in the second experiment, over that in the first. 60 15 to the dtiply by 8; tne for each horse- power. One i irse-] owi r will work 12 power-looms, with the prepa For Paper Mills.—A beating machine requires about 7 horse-power. The new papermachines require to 2 1-2 horse-power '; 3 1-2 horse-power will prepare 1 ton old rope per week, working ten hours per lay.—Fcnwick. Steam-, ed In drive various hinds of Ma. chinery. A series of experiments instiuted by Mr. Davison, at Truman and Co.'s Brewery, to ascertain the power required to drive various kinds of machinery, gave the following results : 1st. That an engine which indicated 50 horses power wnen fully loai ■ I. after the load and the whole ot the machinery were thrown off, 5 horses, or one- tenth of the whole power. 2nd. 190 feet of horizontal, and 180 feet of upright shafting, with 34 bearings, whose superficial area was 3300 square inches, together with 11 pair of spur and bevel wheels, varying from 2 feet to 9 feet in diameter, requfced a power equal to 7.65 horses. 3rd. A set of three-throw pumps, 6 inches in diame- ter, pumping 120 barrels per hour, o a height of 165 feet,=4.7 horses.](https://iiif.wellcomecollection.org/image/b21121175_0012.jp2/full/800%2C/0/default.jpg)