The treatment and disposal of waste waters from dairies and milk products factories.

- Great Britain. Water Pollution Research Board

- Date:

- 1941

Licence: Public Domain Mark

Credit: The treatment and disposal of waste waters from dairies and milk products factories. Source: Wellcome Collection.

14/162 (page 4)

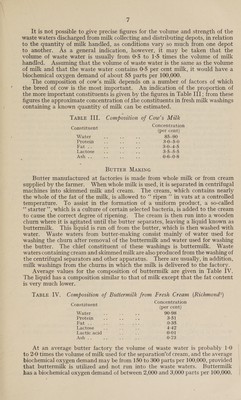

![CHAPTER II]. GENERAL CHARACTER AND QUANTITY OF WASTE WATERS FROM THE MILK INDUSTRY MILK COLLECTING AND DISTRIBUTING DEPOTS T collecting and distributing depots the milk is usually received in churns A of 10 gallons capacity; after cooling it is generally despatched in bulk in railway or road tank wagons. At some depots milk may be pasteurized for local sale. As each churn arrives at the unloading platform at the depot the lid is removed and the milk is poured into a large trough or tank from which it is conveyed to a vat or tank in the depot. The churn and lid are then washed with cold and hot water to which soda and other detergents are usually added. In the larger depots, the churns and lids after draining are transferred to a moving conveyor and passed at a steady rate through a washing plant in which they are cleaned with water and with steam; the washed churns are returned to the farmer. Before despatch in bulk from the depot the milk is either cooled to prevent deterioration during transport or is first pasteurized and then cooled. In the process of pasteurizing, the milk is maintained at a temperature of not less than 145° F. (62-8° C.) for not less than 30 minutes; it is then rapidly cooled. In the cooling plant the milk is brought into contact with tubes or plates which are cooled by means of brine from a refrigerating unit. The waste waters from these processes of bulking and treatment of the milk before distribution consist mainly of water mixed with milk and sometimes contain soda and other detergents. Waste waters of this kind are referred to as “milk washings ’’ in this report. The following are the main sources from which these waste waters are discharged: 1. Washings carrying milk spilt on to the floor during the emptying of churns into the collecting trough. . 2. Milk drained and washed from churns and lids after removal from the _ drainage rack covering the milk collecting trough. Any milk adhering to the churns and lids, after their removal from the rack, drains from them while on the conveyor to the washing plant or is washed out with water and steam in the washing plant. In some plants the drainage from the conveyor is collected and may be utilized. 3. Washing water used to clean the churn-tipping and washing plant after use. . 4. Washing water from the pasteurizing plant. 5. Washings from the cooling plant. 6. Miscellaneous floor washings. The de-oxygenating effect of waste waters containing milk, milk products, and by-products on a river or stream may conveniently be assessed by a determination of their biochemical oxygen demand. In this determination the liquid to be tested is diluted with water containing oxygen in solution and the mixture is stored in completely full, stoppered bottles for 5 days at a temperature of 18° C. As the result of chemical and biochemical activity, the constituents of the liquid undergo oxidation, the extent of which is calcu- lated from the weight of dissolved oxygen absorbed in 5 days from the diluting water. The processes of oxidation are similar to those which occur when the liquid is discharged to a stream, and a knowledge of the biochemical oxygen demand therefore enables an estimate to be made of the polluting character of the liquid. The biochemical oxygen demand of whole milk was found to vary in different](https://iiif.wellcomecollection.org/image/b32179613_0014.jp2/full/800%2C/0/default.jpg)