A catalogue of surgical instruments and appliances manufactured and sold by Down Bros.

- Down Bros. (Firm)

- Date:

- 1906

Licence: In copyright

Credit: A catalogue of surgical instruments and appliances manufactured and sold by Down Bros. Source: Wellcome Collection.

Provider: This material has been provided by The University of Leeds Library. The original may be consulted at The University of Leeds Library.

1602/1674 (page 2180)

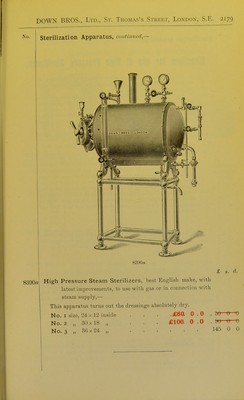

![Stepilization Apparatus, continued,— Directions for use of Higli Pressure Steriiizers. Open air-valve in jacket to allow escape of air, then pour in water through the funnel to about half, fill the jacket as shown by the gauge glass, then close all valves tight. Place the dressings, etc., to be sterilized inside the chamber, close the door and lock tight. If heated by gas, turn on the supply and liglit burner (if heated by steam, oj)en steam supply valve); and when the pressure of steam in the jacket reaches 5 lbs. as registered on tlio pressure gauge, open valve for escape of air, and close it again -when sieam a]ppears. When 10 lbs. is registered on the pressure gauge, open the valves to withdraw air from the sterilizing chamber and form vacuum, and leave them open for five minutes. Then close lower, and after- wards upper, valve. When the pressure reaches iO lbs. in the jacket, open val ve to con- vey steam into the sterilizing chamber—continue this for 20 minutes under 10 lbs. pressure (a uniform pressure can be maintained by regulating the gas-cock or steam supply valve), then turn off steam from the chamber and open the two valves to j)roduc.e vacuum, thusdrying the dressings by removing all contained moisture (the vacuum should be maintained for from 5 to 15 minutes accordins: to the density of the load), then open stop-cock on air filter to admit (filtered) air and destroy vacuum, then release and open door, and dressings may be removed. N.B.—The creation of a vacuum at the beginning of the process, and the withdrawal of the steam from the chamber at the end ensures absolute sterility and also dryness of the dressings. To clean the jacket. This should be done about every ten days, if the apparatus is in daily use, and is carried out as follows : leave about 3 inches of water in the jacket as shown by the gauge glass, and heat up till 5 lbs. jDressure is registered on the gauge, then open valve, permitting the whole contents to be expelled, carrying with it any dexsosit. The cotton wool in air filter should be changed regularly. CAUTION,—Care should be taken never to heat up the sterilizer unless there is water in the jacket; at least inch of water should be shown in the gauge glass when heat is being applied.](https://iiif.wellcomecollection.org/image/b21503084_1602.jp2/full/800%2C/0/default.jpg)