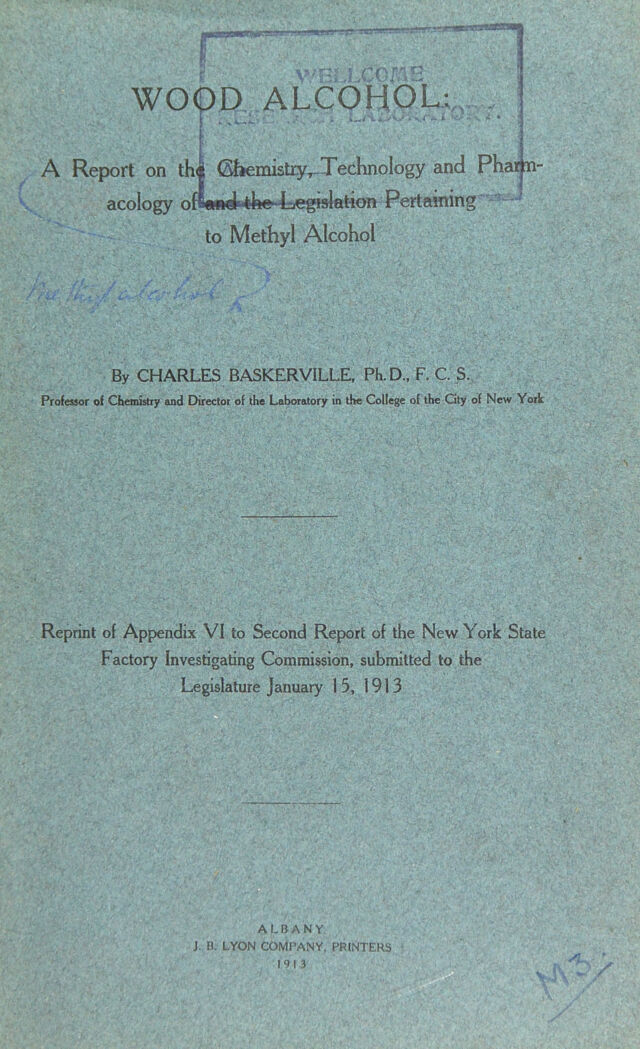

Wood alcohol : a report on the chemistry, technology and pharmacology of and the legislation pertaining to methyl alcohol / by Charles Baskerville.

- Charles Baskerville

- Date:

- 1913

Licence: In copyright

Credit: Wood alcohol : a report on the chemistry, technology and pharmacology of and the legislation pertaining to methyl alcohol / by Charles Baskerville. Source: Wellcome Collection.

14/130 page 928

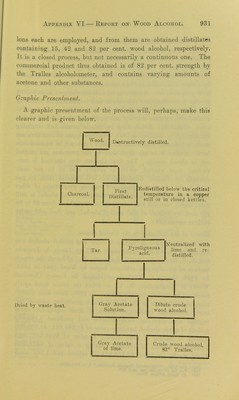

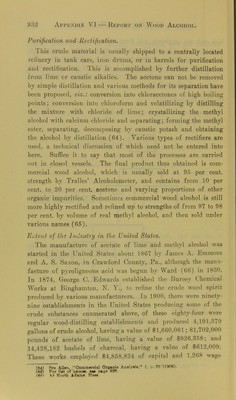

![CHAPTER IJ MANUFACTURE OF WOOD ALCOHOL. Methods of and Materials Used in Manufacture. The destructive distillation of wood is almost the only method of obtaining methyl alcohol in the United States possessed of practical interest, although in Europe it has been proposed to manufacture it by the destructive distillation of peat (55) and it has been obtained as a by-product from vinasse (56). Methyl alcohol may also be prepared by a variety of synthetical reactions (57), and recently a process has been developed for obtaining it as a by-product in the manufacture of wood-pulp by a soluble sulphite process (58). The production from peat, vinasse and wood-pulp is incon- siderable, and more or less incidental; and the synthetical methods are at present too expensive to be practised on a commercial scale. The commercial demand for methyl alcohol is therefore (55) For description of prooess, see W. A. G. von Heidenstam, English Patent 2292, Feb. 5, 1900. . . (56) Vinasse is the residue remaining Jafter the distillation of fermented beet-root molasses. (57) The chief methods proposed are:— J A. From methane. m By chlorination in reflected sunlight (Berthelot, Compt. rend., 46, 916). Incomplete oxidation [Maiimene, Bull. soc. chim., (2), IS, 2431. Oxidation with ozone at ordinary temperatures [Otto, Ann. chim. phys., (7), 13 77] ^ 4 By passing methane and air over finely divided copper (Glock, Ger. Pat. 109014 of 1898; Coquillon, Z. Spiritusind., 23, 182). By oxidation with hydrogen peroxide, ferrous sulphate, monopersulphuric acid, ombined or alone (Lance and Elworthy, Eng. Pat. 7297, March 26, 1906). (2) (3) (4) (5) (6) <B. By combined L, _ . — . By oxidation at 30-50° C., using tan bark as a oontact substance (Hausmann & Co., Ger. Pat. 214155, Sept. 26, 1906). .■* > the dry distillation of calcium formate [Lieben and Rossi, Gazz. chim. Ital., 1371, 164; Lieben and.Paterno, Ann., 167, 293; Friedel and Silva, Bull, soc. chim., (2), 19, 481). n By the electrolysis’of an organic salt. From potassium jmalonate (Peterson, Z. pkysikal. Chem., 33, 714). From potassium jacetato ,(Hoofer Moost, Z. Elektrochem., 10, 833), From sodium ‘acetate, perchlorate, sulphate, land potassium ^carbonate and bicarbonate (Moost, Chem.-Centr., 74, i, 370). d D. From formaldehyde. t . . , ,T. , ,, , . .. -„no. Bv the action of potassium hydroxide (Lieben, Monatsh.,23, 302). «. ,* r 11 lx .w. 1 ma C 11 uri tK .iro tor I In I’ll I !! uri (1) (2) (3) 3 1 (2) By the Toition~of*TghtJon a mixture of it with water (Inghilleri, Z. physiol. ■* Chem., 73, 144). , fl)°m|iy yUstulation^fglycerine,with soda [Ferubach, Bull. soc. chim. (2). 34. 140). (2) By the action of carbon dioxide on sodium glycerate at 180 C. (Loebisch and Fr m nrussfc adiMLinnemann and fsiersoh, Chem. Centr., 39, 390). From Sno by saturation with hydriodio aoid or hydrochloric add (Friedsl, Compt. rendft ^’Bythe action of a zinc salt [Zn (Ca Hs)l upon monoohlor-ether (Henry, Chem. Cent.. at< IT S Pat. 407442, July 23, 1889; Stora Kopparbergs Bergslag Aktieb- dag, (Frinch PaL 40233.. Aprif 23, 1909; Bergstrom, Peplerf.brik.nt, 3, 970. E. F. G.](https://iiif.wellcomecollection.org/image/b28142160_0014.jp2/full/800%2C/0/default.jpg)