Second report of the Departmental Committee appointed to inquire into the ventilation of factories and workshops. Pt. 1, Report.

- Great Britain. Home Office. Committee on Ventilation of Factories and Workshops.

- Date:

- 1907

Licence: Public Domain Mark

Credit: Second report of the Departmental Committee appointed to inquire into the ventilation of factories and workshops. Pt. 1, Report. Source: Wellcome Collection.

89/140 (page 41)

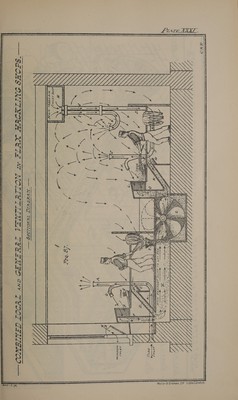

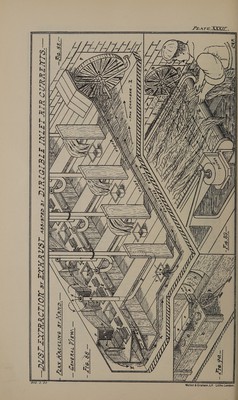

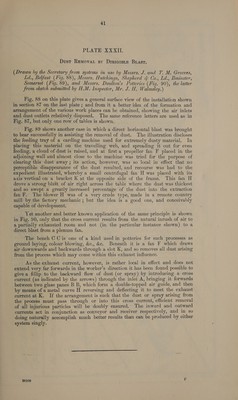

![4] PE AVERYS XL Dust Removar sy Dtriciete Bast, (Drawn by the Secretary from systems in use by Messrs. J. and T. M. Greeves, Ld., Belfast (Fig. 88), Messrs. Hutchings, Shepherd § Co., Ld., Ilminster, Somerset (Hig. 89), and Messrs. Doulton’s Potteries (Fig. 90), the latter from sketch submitted by H.M. Inspector, Mr. J. H. Walmsley.) Fig. 88 on this plate gives a general surface view of the installation shown in section 87 on the last plate ; and from it a better idea of the formation and arrangement of the various work places can be obtained, showing the air inlets and dust outlets relatively disposed. The same reference letters are used as in Fig. 87, but only one row of tables is shown. Fig. 89 shows another case in which a direct horizontal blast was brought to bear successfully in assisting the removal of dust. The illustration discloses the feeding tray of a carding machine used for extremely dusty material. In placing this material on the travelling web, and spreading it out for even feeding, a cloud of dust is raised, and at first a propeller fan F placed in the adjoining wall and almost close to the machine was tried for the purpose of clearing this dust away ; its action, however, was so local in effect that no perceptible disappearance of the dust resulted, and recourse was had to the expedient illustrated, whereby a small centrifugal fan H was placed with its axis vertical on a bracket K at the opposite side of the frame. This fan H drove a strong blast of air right. across the table where the dust was thickest and so swept a greatly increased percentage of the dust into the extraction fan F. The blower H was of a very crude type, made in a remote country mill by the factory mechanic ; but the idea is a good one, and conceivably capable of development. Yet another and better known application of the same principle is shown in Fig. 90, only that the cross current results from the natural inrush of air to a partially exhausted room and not (in the particular instance shown) to a direct blast from a plenum fan. The bench C Cis one of a kind used in potteries for such processes as ground laying, colour blowing, &c., &c. Beneath it is a fan F which draws air downwards and backwards through a slot K, and so removes all dust arising from the process which may come within this exhaust influence. As the exhaust current, however, is rather local in effect and does not extend very far forwards in the worker’s direction it has been found possible to give a fillip to the backward flow of dust (or spray) by introducing a cross current (as indicated by the arrows) through the inlet A, bringing it forwards between two glass panes B B, which form a double-topped air guide, and then by means of a metal curve H reversing and deflecting it to meet the exhaust current at K. If the arrangement is such that the dust or spray arising from the process must pass through or into this cross current, efficient removal of all injurious particles will be doubly ensured. The inward and outward currents act in conjunction as conveyor and receiver respectively, and in so doing naturally accomplish much better results than can be produced by either system singly. 28109 F](https://iiif.wellcomecollection.org/image/b32182107_0089.jp2/full/800%2C/0/default.jpg)