Report of the Director-General of Public Health, New South Wales.

- New South Wales. Department of Public Health

- Date:

- [1940]

Licence: Public Domain Mark

Credit: Report of the Director-General of Public Health, New South Wales. Source: Wellcome Collection.

57/72 page 57

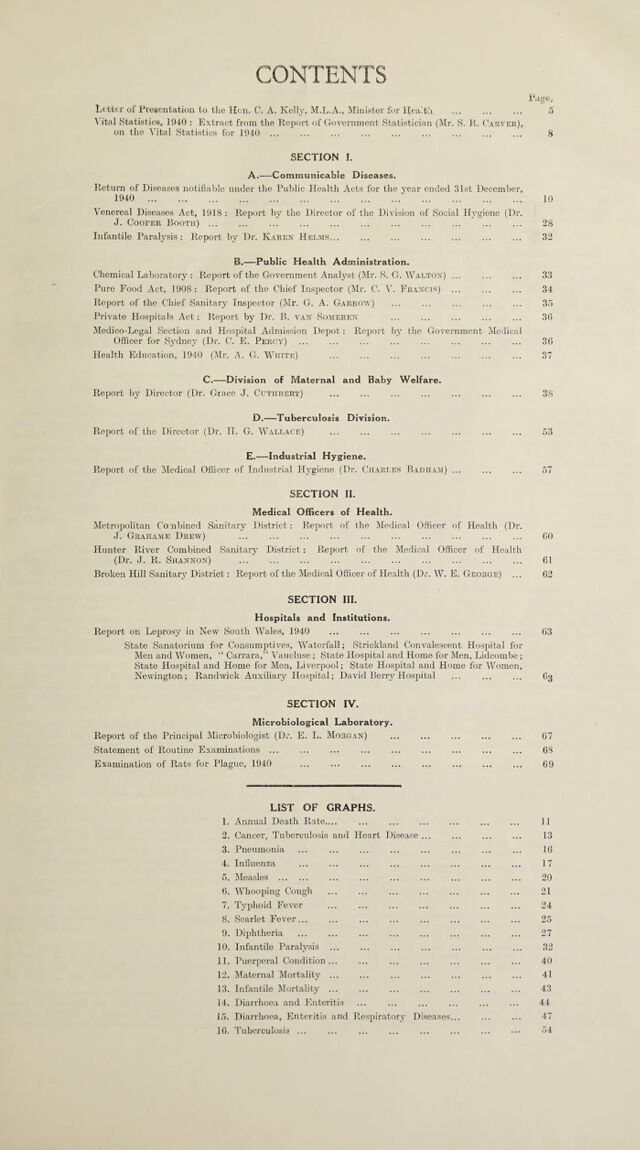

![SECTION I. E—INDUSTRIAL HYGIENE. Report of the Medical Officer of Industrial Hygiene for the Year Ended 31st December, 11)40. Staff. Medical Officer of Industrial Hygiene-. Charles Badham, B.Sc., M.B., Ch.M., D.P.H. Assistant Medical Officer: Gordon C. Smith, M.B., B.S. Physicist Assistant: H. E. G. Rayner, B.Sc. Chemist Assistant: A. M. Willison, M.Sc. Engineer Assistant: H. M. Whaite, B.E. Laboratory Assistant: A. J. Gavriloff. This division undertakes the investigation of hazards to health in factories, mines and industry generally, and the diagnosis of cases of occupational disease. Co-operation With Commonwealth Department of Health re Health of Munition Workers. In August, 1940, an Advisory Committee was set up by the Commonwealth Government in respect of the health and wel¬ fare of munition workers and of the hygiene of munition establishments. At the request of the Federal Director-General of Health, the services of the Medical Officer of Industrial Hygiene, Dr. C. Badham, were made available as a member Of this committee. Monthly meetings have been held in Melbourne for consul¬ tation and discussion of the various problems met with during inspections of annexes, and technical training schools for munition workers. In addition to attending the committee meetings, Dr. Badham has inspected in New South Wales nine training schools for munition workers, and five munition annexes. In each ease a report dealing with the working conditions and hygiene, and including recommendations, lias been made to the chair¬ man of the Advisory Committee. Efforts are being made to formulate standards with respect to heating and ventilation, lighting, welfare accommodation and hours of work, and to reduce the accident rate and other risks to health from dangerous processes. Dust Diseases of the Lungs. The work cf the Medical Officer of Industrial Hygiene on the investigation of dust diseases and on the special Pneumo¬ coniosis Board of the Workers’ Compensation Commission has continued. A statement was prepared for the Royal Commission inquir¬ ing into the question of compulsory retirement at the ago of 60 years of employees in coal and oil shale mines in New South Wales. Dust Sampling in Railway Tunnels Under Construction. At the request of the Secretary for Railways, exhaustive tests were made on several occasions of the dust hazard in railway tunnels under construction at Hawkesbury and on the new Sandy Hollow-Maryvale line. In both workings the dust exposure was found to be excessive, necessitating improvement of the conditions, and further inspections were made. Asbestos. At the request of the Department of Labour and Industry, an investigation was made of the dust hazard at a factory manufacturing asbestos rope. The air of the factory was vitiated by asbestos dust which was evolved mainly from the willowing and tearing machine, and from the carding machine. Other machines in the factory caused some dust but the amount was much less than from the two above-mentioned machines. Dust sampling by means of the Owens’ Jet Dust Counter showed that the exposure was up to 560 particles per ee. in the air of the work-room. It was recommended that the willowing-tearing machine ami the carding machine be fitted with suitable exhaust ventilation to keep the dust concentration within safe limits. Diatomaceous Earth. At the request of the Department of Labour and Industry, three factories making Tripoli” polisher for brass and nieke] fittings were inspected. It was recommended that the manipulation or weighing of free silica in the form of powdered quartz, diatomaceous earth or any powder containing a high percentage of free silica, be permitted by the Department of Labour and Industry only on the installation of exhaust ventilation, and constant use of same when the process is in operation. Dust in Foundries. At the request of the Silicosis Committee, an investigation was made of the dust hazard at two iron foundries and one ore-milling plant. Tests taken in one foundry showed that— (a) During the use of carborundum dressing wheels, the dust concentration at breathing level was found to be from 600-2,400 particles per cc. This dust appeared to be mainly iron oxide, some carborundum and a little quartz; (b) during the brushing out of the baths,_ the men were exposed to a dust concentration of from 800-2,300 particles per cc. This dust appeared to be mainly silicate, probably from the material used for facing the moulds; (c) in the sand-room, the men were exposed to from 700- 900 particles per cc. The particles were very small and their nature could not be determined; (d) the general factory air had 238 particles per cc., mostly small (0.5 microns) some of which were smoke. Dust From Abrasive Wheel Dressing. An investigation was made of the dust exposure of men engaged dressing carborundum and emery wheels in a local factory. At the time of inspection only one dressing wheel was in operation, whereas usually four were in operation. Slides taken by Owens’ dust counter at breathing level whilst emery wheels were being dressed varied from 357 to a ,220 particles per cc.. and when dressing carborundum wheels, from 1.134 to 1.430 particles per cc. The dust concentration cf the general room air varied from 626 to 1,000 particles per cc. The wheels were dressed under exhaust hoods, but these were inefficient. It was considered that the employees were unduly exposed to dust. The factory in question has since moved to a new building and has installed efficient exhausts to the dressing wheels. Manufacture of Steel V/ool. At the request of the Department of Labour and Industry, an investigation was made of the possible dust hazard during the manufacture of steel wool. The dust consisted of steel particles about 1 micron in size, but the concentration was below 100 particles per cc. (Owens’). Larger particles settled on rafters, etc. It was not considered that there was any marked hazard in this industry. Dust Hazards at Pipe Works. At the request of the Industrial Commission, a report was furnished on the working conditions at the galvanizing plant, blower box, zinc dross house, zinc packing house, shot blast and sand blast of a pipe works. Lead Poisoning. One hundred and sixty-seven individuals, suspected of having lead poisoning, were examined by this division; of these, forty- seven were diagnosed as having lead poisoning with disability, and the remaining one hundred and twenty as having no disa¬ bility or not being lead poisoned. The industries which fur¬ nished cases of lead poisoning were as follows: Painting Industry (17); Manufacture of Accumulator Batteries (13); Glass Industry (8); Lead Smelting (4); Printing, Plumbing, Sheet Metal Work, Ship-breaking, Pipe-laying (1 each). The examination of blood smears submitted bv medical officers in charge of six factories engaged in the manufacture of accumulator batteries and battery parts, one factory engaged vitreous enamelling, one lead smelting firm and a glass works has been continued, and during 1939 1,328 slides and in 1940 2,597 slides were reported on.](https://iiif.wellcomecollection.org/image/b31485315_0057.jp2/full/800%2C/0/default.jpg)