Final report of the Committee on the Production and Distribution of Milk.

- Great Britain. Committee on the Production and Distribution of Milk.

- Date:

- 1919

Licence: Public Domain Mark

Credit: Final report of the Committee on the Production and Distribution of Milk. Source: Wellcome Collection.

68/104 (page 60)

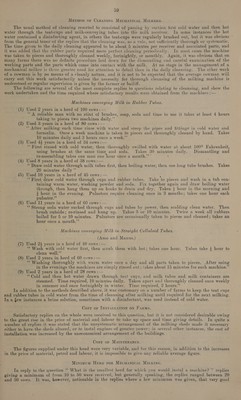

![results had been obtained. This may indicate that the management in these small herds was more thorough, and that more attention was given by the farmer himself than was usually the case with large herds. In the latter, the success or non-success of the plant often depends on the cowman in charge. EstTIMATes or SAVING In LABOUR AND Cost By MEcHANICAL MILKING. There was great variation in the replies given to the questions on these points. In many instances it was stated that there was no saving in labour or in the cost of production, indeed, in a few instances, it was definitely stated that the cost of production was increased. Others again, pointed out that although the actual labour in milking might be reduced in the use of the machine, the same amount of labour was required for the cleaning of the cowsheds and the feeding of the stock. On the other hand, numerous replies were received giving definite instances as to reduction in the labour required, and figures as to saving in the cost of production. The following are typical replies on these points, together with expressions of opinion on the continued use of the milking machines if sufficient reliable hand milkers were available : — No. Stee Bee 2 Saving in Labour. | Saving in Cost of Production. Be ricci: | 1 35 cows... | 3 years... | One man None, but it enables me to | No, as there is such a lot of keep on milking, which I work to do when the cows should not be able to do are lying in. without it. 2 4 44 ,, ... | Three milkers Shae se aoe Ph ... | Yes, decidedly. 3 28 5s 8. sy. fase [One man Present day pay of one man | No. £75 per annum. 4 9053 53 ,, «.. | 50 per cent. ; Bas ... | 3d. per gallon... ah Bie ik 2 5 BIO, 7 4, + | 50 per cent: sist .. cee | Pays greater percentage on | Certainly. capital than any other machine on farm, as it is used more constantly. 6 of ot aie Two men . ee = .. | Very little Ss Yes, a great advantage in : harvest time. 7 2D Mee ea 1Z. OC, None, but skilled men not | None ... sia Eds ive | INOS required. Jt enables me to carry on with very indifferent labour. 2 8 45 5, 5 aa I hid six milkers when war | I should say at present cost of | I think I should. Several commenced, four joined and I labour, machine would be a men milkers always quarrel. at once putin machine. Have little cheaper, petro] costs so : done it since with two men much. and a boy. 5) 60s Qh es 3 good men milk 60 cows in | It does not save much in cost | No. about 14 hours; a little of production. longer when cows are in full milk thus save three milkers. H)hs8 LOO os In my case 8-10 milkers ae: Yes, certainly. 11 43.0% 7 en None; the only reason I con- | None Certainly not. tinue to use the machine is the great difficulty in getting milkers. 12 4), AM eS 2. One man... ae ie sti 300 a: tie esse 13, 71405 None I found my machine a dead | No, if each milker had to loss, and before I would put milk 14 at a meal. in another I would sell my herd. SUGGESTIONS FOR IMPROVEMENTS IN MACHINES. Many of the suggestions received dealt with small points which apparently had been brought to the operator’s notice in the management of his own machine. It is possible that more careful management in some cases would have obviated the necessity for improvement, for instance, one user said that the pressure on the teat and udder was too severe, which was probably due to his having worked the machine at an un- necessarily high pressure. Another asked for teat-cups adaptable for any size of teat, while a third was more reasonable in asking for different sizes of teat-cups. On this latter point, it is worth noting that some of the earlier machines put on the market supplied teat-cups in 4 or 5 sizes, but later use has apparently shown that so great a variety is unnecessary. The suggestions which appeared to have most force were those which asked for pulsators of simple yet strong construction, and for greater simplification in the construction of the machine so as to facilitate cleansing. One farmer stated that in his opinion stripping by hand should not be necessary, but as it has already been pointed out, many machines will effectively strip the cow at the expense of time and with greater risk of too late detection of udder trouble. A number of users mentioned as a defect that the machines they had in use were too costly. CHANGES IF ANOTHER PLANT WERE TO BE INSTALLED. The majority of the replies on this point were to the effect that the users would prefer the plant which they already had in operation. Several stated that they would use a different type of engine, either smaller for the use of the milking machine only, or larger to enable them to have sufficient power for other work in the farm buildings. Several who had plant with vacuum pipes of 3” diameter stated they would](https://iiif.wellcomecollection.org/image/b32177240_0068.jp2/full/800%2C/0/default.jpg)