Volume 1

Encyclopædia of chemistry, theoretical, practical, and analytical, as applied to the arts and manufacturers / by writers of eminence. Illustrated with numerous wood-cuts and steel-plate engravings.

- Date:

- 1877-1879

Licence: Public Domain Mark

Credit: Encyclopædia of chemistry, theoretical, practical, and analytical, as applied to the arts and manufacturers / by writers of eminence. Illustrated with numerous wood-cuts and steel-plate engravings. Source: Wellcome Collection.

39/1132 page 23

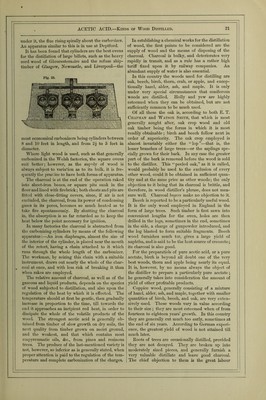

![Dr. Pm. C. 1000 Hectolitres of coal, at 50 frs. the 15 hecto 3,333 33 500 Sieres, halfconls, ofwood,at‘Jfr.20c.,4,000 00 Wases of coke-oven man, 120 00 Wages of six work- men, 450 00 Wages and lodging of two carmen,.... 200 00 Keep of two horses.. 180 00 Salary of director of works, 200 00 Wear and tear, calcu- lated at 10]iercent. on the value of the plant—60,000 frs. .500 00 5 per cent, interest on capital 416 00 Rent of ground and cellarsforcharcoal, 100 00 Frs. 10,099 33 Cr. Frs. C. 1320 Hectolitres of coke, at 49 fr. the 15 hecto. 4,312 00 4.50 Hectolitres small coke, at 32 fr. 50 c. the 15 hecto, 975 00 750 Loads ofcharcoal, at 6 fr., 4,500 00 150 do., second qua lity, 5 fr 7.50 00 50do.,thirdqnality,4lr., 200 00 20 do., powder, 2 fr. .50 c 62 50 200 casks pyroligne- ous acid, at 15 fr., 3,000 00 Tar, 165 00 Frs. 13,964 50 One franc equals lOrf English ; 100 centimes are equivalent to a franc. The French hectolitre is a measure of capacity, containing 100 litres, equal 22-009668 imperial gallons; 4-5434579 litres equal an imperial gallon. The temperature at which wood is distilled makes, according to Chapman, a marked difference in the nature of the products obtained from it. In a series of experiments made on oak sawdust, he obtained from 13 to 27 per cent, of the sawdust in the form of charcoal, simply by varying the temperature at which the charring was effected. The higher the temperature the smaller the yield of charcoal. When, however, the heat was very gradually in- creased, so that the charring was effected at a low temperature, the yield was invariably only slightly less than it was when the wood had been charred at a permanently low temperature; so that the large yield in the case of the low temperature was not due to imperfect charring. When the wood is very rapidly charred the amount of liquid which distils from it is always less ! than when it is charred slowly, and the amount of I uncondensable gas is very greatly larger. The amount of acetic acid is also larger at a low than at a high temperature. It is generally admitted that the largest amount of acetic acid is obtained with large ovens at a low temperature. On the other hand, when naphtha is desired, it s believed that small ovens very highly heated give the greatest yield; though the large quantity of permanent gas generated must carry off with it much of the volatile spirit. It is still a disputed point amongst distillers as to whether wrought or cast iron is the better material for the ovens. According to the experience of one manufacturer wrought-iron ovens will hardly last thirty charges; according to another they will last five to six years. Chapman considers that when properly protected by brickwork, and with careful firing, wrought iron is quite equal to cast iron in point of endurance. It is, of course, much less liable to crack, and may be made very much thinner, there- fore wasting less fuel. Its disadvantages are, that vessels made of it easily lose their shape by over- heating, and are somewhat apt to leak at the joints. Wrought-iron ovens are always furnished with cast- iron exit pipes and doors, as wrought iron is rapidly attacked by the acid vapours, unless it is sufficiently hot to prevent any condensation upon its surface. Wrought iron is only employed for the construction of cylindrical retorts. Cast iron is most commonly employed. Its advan- tages are obvious; the whole oven may be, and fre- quently is, cast in one piece, so that there is no chance of leakage from it. Its disadvantages are, that it is apt to crack with the fire, and when cracked it is difficult to repair it satisfactorily; this is especially the case with cylindrical ovens cast in one piece. Square ovens are frequently built up of plates of cast iron bolted together. The following are the dimensions of various ovens in actual use :— Description of Oven. Length. Diameter. Depth. Breadth. Area. Feet. Feet. Feel. Feet. Cubic Feet 1 Wrought iron, cylindrical, 7-0 5-0 — — 137-50 2 9-5 3-5 — — 91-39 3 Cast iron, a 10 0 3-5 — — 96-00 4 100 3-1 — — 115-40 5 <4 4-5 30 — — 31-77 6 7-0 2 5 — — 34-30 7 << rectangular. 7-0 — 4-'0 3-66 115-29 8 (i 9-5 — 5-00 3-66 174-00 9 ti 10-0 — 4-33 4 33 187-76 Of these ovens. Nos. 1, 3, and 4 have been reported upon very favourably. No. 5 is an old pattern, not likely to be ever again constructed, though still in use. No. 6 is used to prepare special kinds of char- coal, and in some works to burn hea-ry timber from ship breakers’ yards. No. 7 is not an approved pat- tern. No. 8 is considered to be a very good oven; some ovens constructed on the same pattern have been in use for twenty years. No. 9 is the largest square oven which has been built. Whatever the form of oven employed, it must be properly protected with brickwork from the direct action of the fire. No. 1 is protected for two-thirds of its circumference; one fire heats two of these ovens. No. 2 is similarly protected, but each oven has an independent fire. Nos. 3 and 4 are only pro- tected at the bottom; they have a separate fire to each, though occasionally two ovens of the dimen- sions of No. 4 are heated by one fire. Nos. 5 and 6 have each a separate fire. All the rectangular ovens have a separate furnace. As a rule, they are protected with brickwork as to their bottom plates only. The composition of the permanent gas- passing](https://iiif.wellcomecollection.org/image/b28127055_0001_0039.jp2/full/800%2C/0/default.jpg)